For gluing acrylic, you want a glue that works. Solvent-based cements are the top-tier choice. They create a permanent, invisible bond by chemically welding the acrylic pieces, resulting in the strongest possible bond. For other tasks, like quick repairs or bonding acrylic to different materials, you can use specialized super glues or UV-curing adhesives.

Did You Know? The demand for high-performance acrylic adhesives is growing rapidly. Technological advancements are driving this trend, with the global market for glue works expected to reach $16.0 billion by 2035.

Acrylic cement for professional acrylic bonding

For a truly professional finish, you should use acrylic cement. This method creates the strongest and cleanest bond because it does not simply stick the pieces together; it chemically welds the plastic into a single, solid piece.

How solvent glue works

Solvent cement works by chemically softening the surfaces of the acrylic you want to join. When you press the pieces together, the softened surfaces fuse. This process creates an initial bond in just a few minutes. The full strength of the weld develops over the next 24 hours, resulting in a permanent and often invisible bond. This type of bonding is ideal for creating seamless joints.

Types of acrylic cement

You will find two main types of acrylic cement, differing in their thickness, or viscosity.

- Thin, Water-Like Cements: Products like Weld-On 4 or a thin Tensol cement are very watery. They are perfect for joints that fit together tightly. This thin liquid flows into the seam through a process called capillary action, creating a very clean bond.

- Thicker, Syrup-Like Cements: Products like Weld-On 16 or Tensol 12 are thicker. You should use this type of tap acrylic cement when your acrylic pieces have small gaps. The thicker consistency helps fill these gaps to ensure a strong connection.

Application techniques

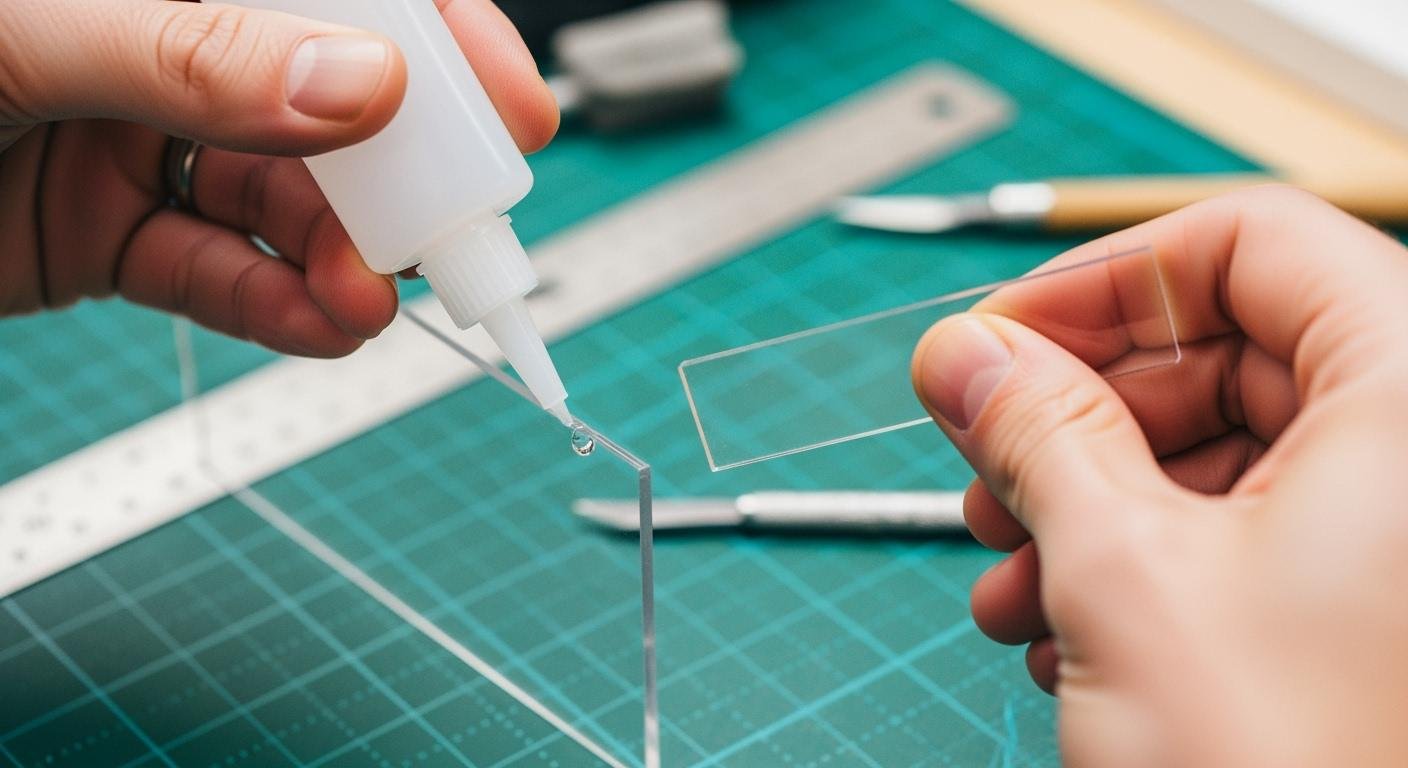

Proper application is key for a successful acrylic bonding project. This step-by-step guide to gluing acrylic will help you achieve a great result. First, gather your tools. You will need a special applicator bottle or a syringe with a needle tip for precise control.

Here is how to bond acrylic to acrylic using the capillary method:

- Prepare Your Pieces: Make sure the acrylic parts fit together perfectly without any gaps. You can use masking tape to hold them in place.

- Apply the Cement: Place the needle of your applicator at one edge of the joint. Gently squeeze the bottle as you pull it smoothly along the seam. The thin tap acrylic cement will wick into the joint.

- Let It Set: The initial bond forms in seconds. You should wait at least three hours before handling the project. The bond will reach its maximum strength in 24 to 48 hours.

Safety First! Preparation tips for bonding acrylic: These cements release strong fumes. Always work in a well-ventilated area and wear proper safety gear, including chemical-resistant gloves and safety goggles. Read the product’s safety data sheet before you begin. This is how glue works safely and effectively.

Cyanoacrylate: A versatile choice for gluing acrylic

While solvent cement is best for welding acrylic to itself, cyanoacrylate (CA), commonly known as super glue, is a fantastic choice for other jobs. It is perfect for quick repairs and for projects that involve different materials. However, you must use the right type of CA glue to avoid a common issue called “hazing” or “blooming.” This happens when fumes from the glue settle on the acrylic and leave a white, powdery residue.

When to use super glue

You should reach for super glue in specific situations where solvent cement isn’t the right tool. Its ability to create a strong bond between different surfaces makes it incredibly useful.

Use super glue for projects like:

- Quick Repairs: It’s great for fixing small cracks or reattaching a piece that has broken off.

- Multi-Material Bonding: It is the best option when gluing acrylic to other materials. You can use it for making display cases with wood frames or attaching an acrylic window to a metal sign.

- Small Parts: When you are working with tiny or delicate acrylic pieces, super glue provides a fast, strong hold without the risk of melting the part like a solvent might.

Application best practices

To get a clean, strong bond with super glue, you need to prepare your surfaces and choose the right product. How this glue works depends heavily on your preparation.

- Clean the Surfaces: First, clean the acrylic with a mild soap and water solution.

- Remove All Residue: Wipe the area with isopropyl alcohol on a lint-free cloth to remove any remaining oils or dust.

- Ensure It’s Dry: Let the surfaces dry completely before you start gluing acrylic.

To prevent hazing, choose a “plastic-safe” or “gap-filling” formula. These are often thicker gels that have fewer volatile fumes. This ensures your final bond is clear and strong.

Pro Tip: Avoid Solvents on Mirror Acrylic Never use a solvent cement like Weld-On on the back of mirror acrylic. The solvent will eat through the gray backing and destroy the reflective mirror layer. For bonding mirror acrylic, a plastic-safe cyanoacrylate is a much safer and more effective choice.

UV-curing adhesives for perfect clarity

UV-curing adhesives offer incredible control and a crystal-clear finish. This type of glue remains a liquid until you expose it to a specific wavelength of ultraviolet (UV) light. This unique feature gives you complete control over the bonding process, making it ideal for high-stakes aesthetic projects where perfection is key.

The advantage of on-demand curing

The main benefit of UV glue is its on-demand curing. Because the adhesive stays liquid until you are ready, you have plenty of time to position and reposition your acrylic parts perfectly. This ability to achieve precise alignment is crucial for delicate assemblies where even a tiny mistake matters. Once you are satisfied with the placement, a flash of UV light creates a strong bond in seconds.

This method offers several other advantages:

- Rapid Curing: The glue works fast, curing in seconds. This speeds up your assembly process.

- Exceptional Strength: UV adhesives create a durable bond. For example, some UV-cured acrylic adhesives can have a tensile strength of 1900 psi.

- Reduced Waste: You can apply the glue precisely, and the instant cure means less mess and material waste.

- Safer Environment: These glues cure at room temperature. This process uses less energy and creates a safer workspace compared to methods requiring heat.

How to use UV glue

Using UV glue is straightforward, but you must follow the correct steps to ensure a strong, invisible connection. At least one of the acrylic pieces you are joining must be clear to allow the UV light to pass through and cure the adhesive.

Follow these steps for a flawless result:

- Prepare the Surfaces: Clean the acrylic surfaces with isopropyl alcohol and a lint-free cloth to remove any dust or oils. Let them dry completely.

- Apply the Adhesive: Place a small amount of the UV adhesive on one of the surfaces. Join the parts together, making any final adjustments to their position.

- Cure with UV Light: Shine a UV lamp on the joint. You will need a light source that emits the correct wavelength, typically between 365 nm and 405 nm, with an intensity over 50 mW/cm². The bond will set in just a few seconds.

- Test Your Work: Always test your bonded assembly to confirm the connection is strong and durable for its intended use.

Important Tip! 💡 The UV light must be able to shine through the acrylic to reach the entire glue line. If you are bonding two opaque materials, this method will not work.

Glue comparison and recommendations

You have several great options for gluing acrylic. The right choice depends on your project’s specific needs. This guide to choosing the right plexiglass glue will help you compare your options and make the best decision for your work.

Comparing your options

To find the perfect adhesive, you need to compare their strengths. Each type of glue offers different benefits in terms of strength, clarity, and how easy it is to use. This table breaks down the key differences between the three main types of acrylic adhesives.

| Glue Type | Bond Strength | Final Clarity | Ease of Use | Best Use Case |

|---|---|---|---|---|

| Solvent Cement | Very High | Excellent (Invisible) | Low (Requires practice) | Seamless joints, structural acrylic projects |

| Cyanoacrylate | High | Good (Risk of hazing) | Medium (Bonds instantly) | Quick repairs, bonding acrylic to other materials |

| UV-Curing Glue | High | Excellent (Crystal-clear) | High (Allows repositioning) | Flawless finish, high-end aesthetic displays |

What is the best glue for plexiglass?

For most projects that involve bonding plexiglass to itself, the answer is clear. The best glue for plexiglass is a solvent cement like Weld-On. This is because you are not just sticking the pieces together; you are chemically welding the acrylic. This process creates a single, solid piece with incredible structural integrity. The bond becomes as strong as the acrylic itself.

When you need the strongest possible connection for your project, solvent cement is the professional choice. For example, a heavy-bodied cement like Weld-On 16 is perfect for bonding plexiglass when you have small gaps to fill. Using the right cement ensures a permanent, durable result.

Pro Tip: For Strength, Weld It! 🏆 When your project’s success depends on strength and durability, always choose a solvent cement. It is the best glue for plexiglass because it creates a permanent chemical weld, ensuring your acrylic construction lasts.

When gluing acrylic, your project’s needs will guide your choice. For the strongest and most professional finish, you should choose an acrylic cement. This method creates a permanent chemical bond.

Quick Recap:

- Cyanoacrylate (Super Glue): Use this for quick fixes or to bond acrylic to other materials.

- UV Glue: Select this for a flawless aesthetic bond where you need perfect clarity and control.

Choosing the right adhesive ensures a durable and clean bond for your acrylic project.

FAQ

Can I use a hot glue gun on acrylic?

You should avoid using a hot glue gun on acrylic. The high heat can easily melt or damage the plastic surface. The bond is also very weak and not suitable for a permanent or structural connection. For better results, choose an adhesive made for plastics.

Will Gorilla Glue work on acrylic?

Yes, some Gorilla Glue products work well. You should use their cyanoacrylate formulas, like Gorilla Super Glue Gel. Avoid the original brown Gorilla Glue, as it expands and does not bond well to smooth plastics like acrylic. Always check the product label for compatibility.

Why did my super glue turn the acrylic white?

That white film is called “hazing” or “blooming.” ☁️

It happens when glue fumes settle on the surface. You can prevent this by using a “plastic-safe” or gel super glue. Working in a well-ventilated area also helps reduce the effect significantly.

See Also

Your Comprehensive Guide to Selecting and Utilizing Acrylic Table Stands

A Complete Handbook for Choosing and Maintaining White Acrylic Trays

Exploring Impact-Modified Acrylic: Understanding Its Definition, Features, and Uses

Edge Bonding Explained: Process, Definition, and Its Role in Acrylic Manufacturing

Acrylic Sign Holders: Definition, Key Features, and Practical Applications Explained