You might look at your favorite acrylic standees and notice their high price tag. That cost is not a random number. It is a direct result of the materials used, the complex manufacturing process, and current market trends.

Anmerkung: This inside look explains the real value and price of these popular collectibles in 2026, showing what truly goes into making them.

The Rising Cost of Raw Materials

The journey of an acrylic standee begins with its raw materials. The price of these materials has a major impact on the final product. Understanding them is the first step to understanding the price tag.

Petroleum and MMA Resin Prices

Acrylic is not a naturally occurring material. It is a type of plastic. Its full name is polymethyl methacrylate (PMMA). The core ingredient for PMMA is a liquid called methyl methacrylate (MMA) resin.

MMA resin is created from petroleum products. This directly links the cost of acrylic to global oil prices. When oil prices go up, the price of making MMA resin also increases. This change affects every industry that uses acrylic. Manufacturers must pay more for their basic materials, and this expense is passed on to the consumer.

Demand for Premium & Recycled Acrylic

Today’s market demands higher quality materials. Consumers want acrylic standees with better clarity, durability, and scratch resistance. These premium-grade acrylic sheets are more expensive to produce.

There is also a growing demand for sustainable options, like recycled acrylic. Creating eco-friendly materials can be a complex and expensive process.

A Look at Recycled Acrylic Costs Some recycled acrylics, like Recrylic, have achieved price parity with new (virgin) acrylic. This makes it an easy choice for companies wanting to be sustainable without extra expense. However, this is not always the case for all recycled types.

For example, producing recycled acrylic fiber (rPAN) involves several cost factors:

- Production can be 10-15% more expensive than making new acrylic fiber.

- Environmental rules can add another 5-10% to production costs initially.

- Despite this, many brands are willing to pay an 8-12% premium for certified recycled materials.

This mix of demand for both premium and eco-friendly materials adds to the overall price of the high-quality sheets used for your collectibles.

The Production Process for Acrylic Standees

Creating an acrylic standee is a multi-stage process. Each step uses special machinery and skilled labor. This manufacturing journey is a major reason for the final price of the collectible. It is an energy-intensive process that adds significant value and cost.

Advanced Printing & Inks

The vibrant, detailed artwork on acrylic standees comes from a special printing method. This method is called UV printing. It is very different from printing on paper or cardboard. UV printers deposit multiple layers of ink directly onto the acrylic. Powerful UV lamps then instantly cure, or harden, the ink. This creates a durable, scratch-resistant image with bright colors that will not fade easily.

The ink itself is a significant expense. UV-curable inks are more expensive than standard inks used for paper products. The higher price ensures a higher quality finish.

Ink Cost Comparison The cost per square meter for UV ink can be almost double that of standard water-based inks.

| Item | Water-Based Flexo Ink | UV Ink |

|---|---|---|

| Ink Price per kg | $6–$8 | $18–$22 |

| Cost per m² (average) | $0.011–$0.016 | $0.022–$0.033 |

The machinery required for this process is also a major investment. These are not desktop printers. They are large, heavy, and expensive industrial machines built for high-quality production.

Example: Industrial UV Printer Specifications This table shows the specifications for a typical flatbed UV printer. Notice the high price and complex features like multi-layer printing.

| Feature | Specification |

|---|---|

| Model | ColDesi UV 300H3F Flatbed Printer |

| Price | $44,995 |

| Print Size | 914 x 609 mm (36 x 24 inch) |

| Ink Type | CMYK + White and Varnish |

| Print Heads | 3 x Epson I3200-U1 |

| Key Features | Multi-layer printing, auto white ink circulation |

Precision Laser Cutting

After printing, each standee must be cut from the large acrylic sheet. Manufacturers use high-precision CO2 lasers for this job. These lasers can follow complex digital patterns. This allows for the unique and intricate shapes of characters and their accessories.

These powerful machines consume a lot of electricity. The laser itself is just one part of the total energy usage. Other necessary equipment also adds to the power bill.

- Fume extraction system: 300-2200W

- Water cooling system: 100-720W

- Air assist pump: 60-160W

Maintenance is another ongoing expense. The CO2 laser tube, which does the cutting, is a consumable part. It has a limited lifespan of around 1,000 to 2,000 hours of use. A replacement tube can cost between $100 and $300. If a technician is needed for repairs, the service call alone can be expensive. An on-site inspection might cost $350 for the first hour, with additional costs for labor and parts. These operational costs are factored into the price of every standee produced.

Manual Finishing and Labor

The production process does not end with the laser cutter. A surprising amount of manual work is still needed to prepare each standee for sale. This “finishing” stage is a hidden cost that adds to the final price.

Skilled workers perform several key tasks:

- Peeling: Each piece of cut acrylic has a protective film on both sides. Workers must carefully peel this film off without scratching the surface.

- Quality Control: Every single standee is inspected for printing errors, cutting mistakes, or other defects. This ensures a high-quality product reaches the customer.

- Assembly: Workers gather the printed character, the base, and any other parts. They package them together, ready for shipping.

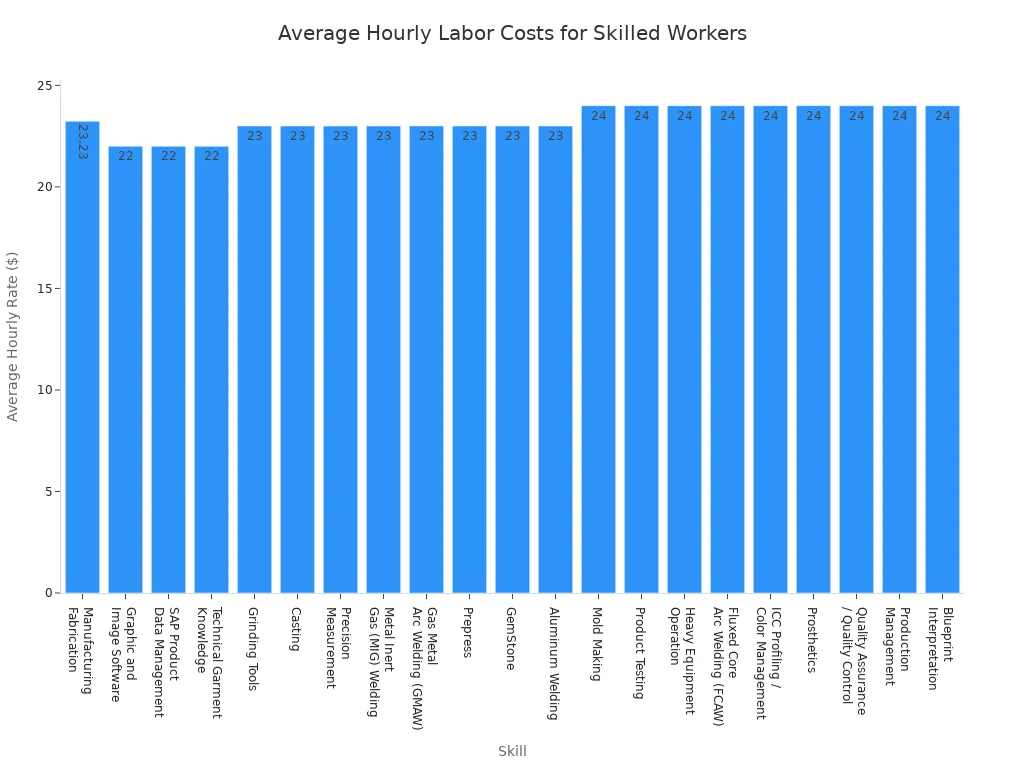

These tasks require time and skill. The people who perform these jobs are paid a fair wage for their work. Skills like quality assurance and production management are essential for a smooth operation.

As the chart shows, hourly rates for skilled manufacturing labor often range from $22 to $24. This labor cost is a crucial part of the total expense of making each standee.

Cost in Context: Standees vs. Other Collectibles

To understand the price of an acrylic standee, it helps to see where it fits in the world of collectibles. The price makes more sense when compared to other popular merchandise, from simple paper goods to high-end figures. This comparison highlights the unique value that standees offer.

Value Compared to PVC Figures

Many fans collect detailed PVC figures of their favorite characters. These are often seen as the top tier of anime collectibles. However, they come with a very high price, frequently ranging from $100 to $300. This is where acrylic standees offer great value.

The material difference is a key factor.

- PVC is a more affordable raw material, often 30-40% cheaper than solid acrylic.

- Acrylic is considered a premium material. Its higher price comes from its excellent optical clarity and harder surface.

While more expensive than a poster, an acrylic standee provides a durable, three-dimensional presence on a shelf for a fraction of the price of a PVC figure. Larger or more complex standees can even rival the shelf presence of smaller “prize figures,” giving fans a satisfying display without the high cost. They provide a perfect middle ground for collectors, offering excellent visual appeal and quality.

The Small-Batch Customization Premium

The number of standees produced in a single batch has a huge impact on the price of each one. Many standees, especially those from independent artists or for niche anime collectibles, are made in small quantities. This small-batch production carries a premium.

Manufacturers benefit from economies of scale. Ordering more units at once allows them to buy raw materials in bulk and run their machines more efficiently. This lowers the price for each standee.

The biggest price drop happens when moving from very small orders to medium-sized ones. This is because the initial setup costs (preparing the printer and laser cutter) are spread across more units.

This table shows how the per-unit price changes with order size.

| Production Volume | Per-Unit Cost |

|---|---|

| 50-100 units | $15–$20 |

| 200-500 units | $10–$15 |

| 500-1,000 units | $8–$12 |

| 1,000+ units | $7–$10 |

This pricing structure shows the economic value of larger production runs. A standee from a massive, popular series will often be cheaper than one from an indie creator who can only afford a small batch.

Supply Chain and Economic Factors

The price of an acrylic standee is not just about materials and manufacturing. Global economics and the supply chain also play a big role. These outside forces can add significant expenses before the product ever reaches a store shelf.

Global Shipping and Tariffs

Most acrylic standees are made in Asia. This means they must be shipped across the world to reach customers in North America and Europe. The price of international shipping can change quickly and dramatically.

Shipping rates are often unpredictable. Prices can rise or fall based on global events, fuel prices, and the number of available shipping containers. These changes directly affect the final price of imported goods.

As of late 2025, shipping rates from Asia have seen notable increases, adding to the expense.

| Route | Change Since Early 2025 | Rate (per 40-ft container) |

|---|---|---|

| Asia to US West Coast | +22% | $2,096 |

| Asia to US East Coast | +2% | $2,930 |

On top of shipping, governments add taxes called tariffs to imported goods. The raw acrylic sheets used to make standees face a general import duty of 6.50% when entering the United States. This extra fee on the raw material increases the base cost for manufacturers.

Limited Supply vs. High Demand

The simple rule of supply and demand also affects standee prices. The popularity of anime, games, and indie art has created a huge demand for this type of merchandise. Fans are eager to collect items featuring their favorite characters.

However, the number of high-quality manufacturers is limited. These factories can only produce so many standees at once. When demand is higher than the available supply, prices naturally go up. This is especially true for limited-edition or exclusive standees released for special events. The rarity and high demand combine to create a premium price for these sought-after collectibles.

The price of acrylic standees reflects several key factors.

- Volatile raw material costs

- A complex manufacturing process

- Economic pressures like shipping and small-batch production

These items offer great value compared to other collectibles. They provide a durable, high-quality display without the high cost of a PVC figure. This positions them as a unique value for fans. Ultimately, the 2026 price is not for a simple piece of plastic. It represents the quality and value of a custom-made product.

FAQ

Why are acrylic standees more expensive than acrylic keychains?

Standees use significantly more acrylic material than keychains. They are larger and include a separate base piece. This increases material costs. The production process also takes more time for printing and cutting, which raises the final price.

Are standees from big companies cheaper than from indie artists?

Yes, they often are. Big companies can order thousands of units. This large volume lowers the cost for each standee. Independent artists usually order small batches. Small batches make each individual standee more expensive to produce.

Will acrylic standee prices go down in the future?

It is unlikely. Several factors keep prices firm.

- The cost of petroleum, a key ingredient, is unstable.

- Global shipping expenses can increase unexpectedly.

- Demand for high-quality production remains strong.

These factors suggest prices will likely stay the same or even rise.

Does the artist get more money if a standee is expensive?

Not necessarily. The high price of a standee first covers production costs. These costs include materials, printing, and labor. The artist’s final profit depends on their sales volume after paying for all these initial expenses.

See Also

Exploring Premium Acrylic Stand Tables: Design and Material Insights

Your Comprehensive Guide to Acrylic Table Stands: Everything You Need

Innovative Uses for Acrylic Tabletop Stands in Retail Showcases

Acrylic Sign Holders: Definition, Key Features, and Practical Applications

Acrylic Trophies and Awards: Definition, Features, and Diverse Applications