Acrylic standees are primarily made from a durable, clear plastic. This material is a type of acrylic called polymethyl methacrylate (PMMA). The final product is a combination of several key components.

A finished standee brings together the main acrylic body, vibrant cured ink for the artwork, and sometimes special finishes or protective layers. This mixture of materials creates the high-quality collectibles you see.

Core Materials of Acrylic Standees

The foundation of any high-quality standee is its core material. The choice of material directly impacts the final product’s clarity, durability, and overall appearance. For acrylic standees, this core component is a specific type of plastic with impressive properties.

What is PMMA Acrylic?

Polymethyl methacrylate, or PMMA, is the scientific name for the acrylic used to create these collectibles. It is a transparent thermoplastic known for its strength, light weight, and exceptional clarity. PMMA is often used as a shatter-resistant alternative to glass. Its optical properties are a major reason for its popularity in products like acrylic standees.

PMMA has a remarkable light transmission rate of over 92%. This is even higher than most types of glass, which typically transmit between 80% and 90% of light. This superior clarity ensures that the printed artwork appears vibrant and sharp, without any tint from the material itself. The different materials work together to create a premium product.

💡 A Note on Thickness You will often find that the main character piece of a standee is made from 3mm thick acrylic. The base is usually thicker, around 5mm, to provide a stable and sturdy foundation.

Cast vs. Extruded Acrylic

Acrylic sheets are manufactured using two primary methods: casting and extruding. The method used affects the properties of the final materials.

- Cast Acrylic: This process involves pouring liquid acrylic monomer into a mold. The material is then cured under controlled pressure and heat. This method produces a harder, sturdier, and more scratch-resistant sheet. Cast acrylic is ideal for laser cutting, resulting in clean, polished edges for the standee shape.

- Extruded Acrylic: This method involves pushing acrylic through a series of rollers to form a sheet. It is a faster and less expensive process, but the resulting acrylic is slightly softer and can be more prone to scratching.

Most premium acrylic standees use cast acrylic because of its superior quality and durability. The table below summarizes the key differences.

| Feature | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| Manufacturing | Poured into a mold | Pushed through rollers |

| Hardness | Harder and more durable | Softer |

| Laser Cutting | Excellent, clean edges | Good, but can melt slightly |

| Coste | More expensive | Less expensive |

Eco-Friendly Acrylic Options

Sustainability is becoming an important consideration for many collectors and creators. In response, manufacturers have developed eco-friendly acrylic options. It is now possible to find acrylic made from 100% recycled materials.

For example, some companies produce recycled cast acrylic sheets using 100% recycled methyl methacrylate (rMMA). Choosing recycled acrylic significantly reduces the environmental impact. The chemical recycling process for PMMA can lower CO2 emissions by as much as 80% compared to producing virgin acrylic. This makes eco-friendly acrylic a fantastic choice for creating beautiful collectibles while caring for the planet. These sustainable materials offer the same high quality and clarity as their traditional counterparts.

Printing a Custom Acrylic Standee

Once the acrylic material is chosen and cut, the next step is bringing the artwork to life. The printing process is crucial for creating a vibrant and durable custom acrylic standee. Manufacturers use a specialized technique called UV printing to apply designs directly onto the acrylic surface. This method ensures the final product is both beautiful and long-lasting.

The UV Printing Process

UV printing is a modern digital printing method that uses ultraviolet (UV) light to cure ink almost instantly. Unlike traditional inks that dry through evaporation, UV ink hardens immediately when exposed to a specific wavelength of UV light. This process is called photopolymerization.

The printer deposits a layer of liquid UV ink onto the acrylic. A powerful UV lamp follows right behind the print head, exposing the ink to UV light. This triggers a chemical reaction that solidifies the ink and bonds it directly to the acrylic. This rapid curing process creates a durable finish with several key advantages:

- Strong Adhesion: The cured ink forms a robust bond with the acrylic, preventing peeling or flaking.

- Enhanced Durability: The hardened ink layer is highly resistant to scratches, smudging, and general wear.

- Environmental Resistance: The print is better protected against moisture and fading from sun exposure.

To achieve a flawless result for a custom acrylic standee, it is essential to use high-resolution artwork. A resolution of at least 300 DPI (Dots Per Inch) is the standard for high-quality prints. This ensures that every detail of the design appears sharp and clear, without any visible pixels.

Composition of UV Ink

The unique properties of UV ink come from its specific chemical composition. It is not a simple colored liquid. Instead, it is a complex formula where each component plays a vital role. The main ingredients are:

- Monomers and Oligomers: These form the backbone of the ink. They are liquid polymers that create the final solid ink film, providing adhesion, flexibility, and durability for the custom acrylic standee.

- Photoinitiators: These are the most critical components for the curing process. When exposed to UV light, photoinitiators absorb the energy and start a chemical reaction. This reaction causes the monomers and oligomers to link together and solidify, turning the liquid ink into a hard polymer in seconds.

- Pigments: These are finely ground particles that provide the color. They are chosen for their vibrancy and ability to resist fading over time.

- Additives: Manufacturers include various additives to improve the ink’s performance. These can help the ink flow smoothly, prevent bubbles, and create a level surface for a perfect finish on the acrylic.

💡 A Note on Safety The use of UV inks is regulated to ensure safety and protect the environment. Agencies like the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) set standards for handling these materials. This includes rules on workplace ventilation and the use of low-emission inks, making the production of acrylic standees a well-managed process.

Printing Configurations

When ordering a custom acrylic standee, you will encounter different printing options. These configurations affect the final look, feel, and durability of the standee. The three most common types are single-sided, double-sided, and front-printed.

- Single-Sided (Back-Printed): This is the most common and recommended style for acrylic standees. The artwork is printed on the back of the clear acrylic. You view the image through the front of the acrylic, which gives it a glossy finish and a sense of depth. This method also protects the ink layer from scratches and direct contact.

- Double-Sided (Sandwiched): For a premium custom acrylic standee, this option provides a complete view from both sides. The artwork is printed in the middle of the acrylic material. This “sandwiched” effect fully encases the design, offering maximum protection and a seamless look from any angle.

- Front-Printed: In this configuration, the ink is printed directly on the front surface of the acrylic. This results in a matte finish, and you can feel the texture of the ink. While less expensive, this method leaves the artwork exposed and more vulnerable to scratching.

The table below compares the two primary surface printing methods.

| Feature | Front-Printed | Single-Sided (Back-Printed) |

|---|---|---|

| Finish | Matte, ink can be felt | Glossy, viewed through acrylic |

| Visual Depth | Flat appearance | Creates a sense of depth |

| Durabilidad | Ink is exposed, prone to scratches | Ink is protected by the acrylic |

| Coste | Generally less expensive | Slightly more expensive |

Choosing the right printing configuration is key to getting the desired look and longevity for your acrylic standee.

Finishes, Effects, and Accessories

Beyond the core material and printing, special finishes and accessories complete the composition of high-quality acrylic standees. These final touches enhance durability, add visual flair, and ensure the product arrives in perfect condition.

Protective Epoxy Coatings

An epoxy coating is a popular finish that adds a layer of clear, durable resin over the printed artwork. This hard coating acts as a barrier, providing enhanced resistance against scratches and minor abrasions. The process involves mixing a resin and a hardener, pouring it over the acrylic surface, and allowing it to cure. This creates a glossy, dome-like effect that magnifies the artwork and protects it.

Applying an epoxy layer significantly improves the durability of a standee. The hardened surface can resist scratches and impacts from daily use, keeping the artwork safe. This process works for both large and small pieces of acrylic.

Holographic and Glitter Effects

Special effects can make your acrylic standees truly stand out. These effects are typically added in one of two ways.

- Specialty Films: A thin, laser-safe film with a holographic or glitter pattern can be applied to the acrylic. This film has a stunning visual effect that changes with the light.

- Specialty Coatings: Glitter particles can be mixed directly into a UV gloss coating. A holographic effect can also be created by pressing a patterned film onto a wet UV coating, which transfers the shimmering pattern onto the acrylic surface.

These methods embed the effect into the standee, creating a dazzling and dynamic look.

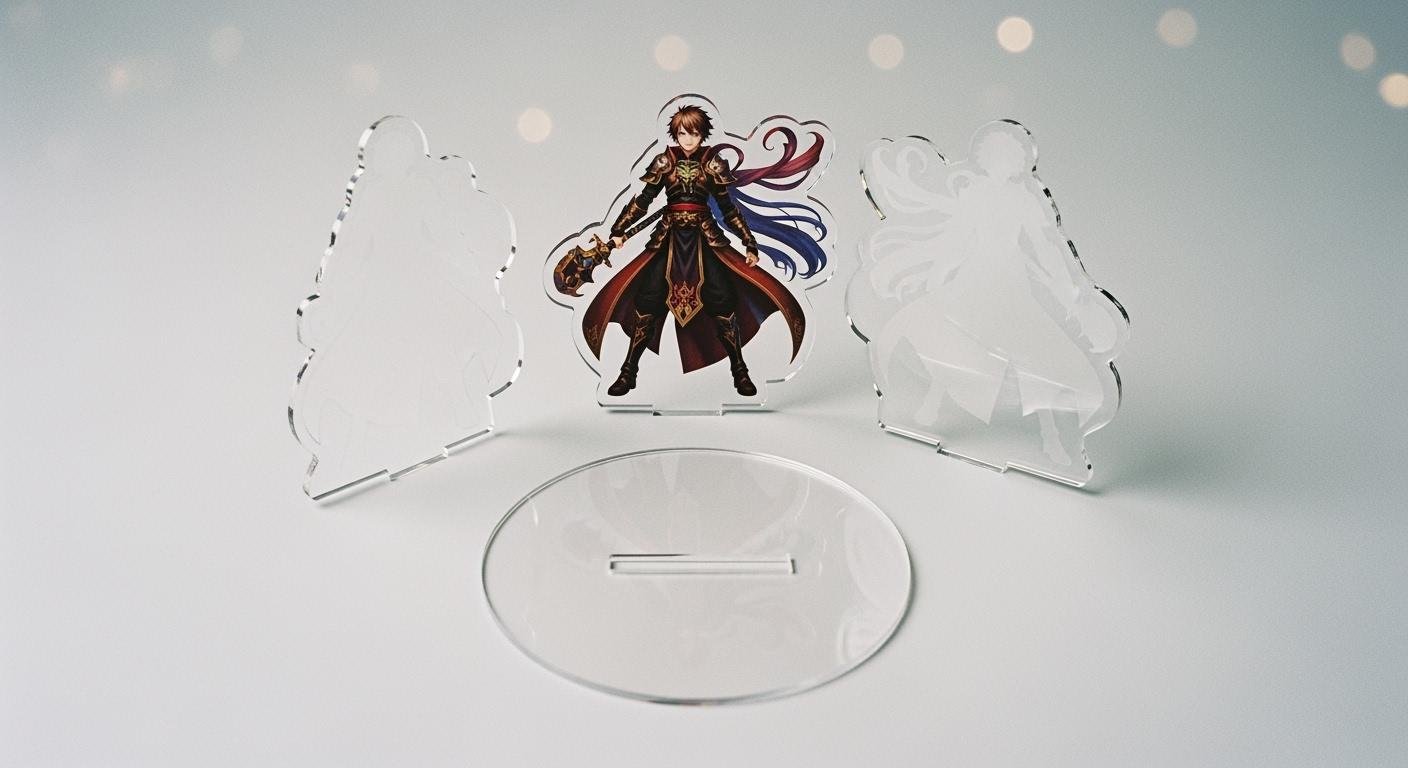

The Base and Protective Film

The final components are the base and a protective film. The base provides stability for the main acrylic piece. Bases are highly customizable and can be made in almost any shape, from simple circles to complex outlines that match the theme of the artwork.

Most new acrylic products arrive with a thin protective film on each side. This film prevents scratches during shipping. You must peel this film off to reveal the clear, glossy surface of the acrylic underneath. It might be hard to see at first, but it is an important final step.

A finished standee is a product of several key materials working together. The core components include:

- A body made from PMMA acrylic, sometimes from 100% recycled acrylic.

- A layer of cured UV ink that forms the vibrant artwork.

- Optional additions like epoxy coatings or special effect films for extra flair.

This combination of materials is what creates durable, high-quality acrylic standees that collectors can enjoy for years.

PREGUNTAS FRECUENTES

How do I clean my acrylic standee?

You should clean your standee with a soft microfiber cloth. Use gentle motions to wipe away dust. Avoid using harsh chemicals or alcohol. These substances can damage the surface of the acrylic and the printed artwork.

Is the artwork printed on both sides?

This depends on the printing configuration.

- Single-sided standees have art on one side.

- Double-sided standees have art printed in the middle. This makes the design visible from the front and back.

Why does my new standee look cloudy?

Your new standee has a protective film on its surfaces. This film prevents scratches during shipping. You need to peel this thin layer off to reveal the clear, glossy acrylic underneath. It can be tricky to see at first.

Will the colors on the standee fade over time?

UV ink is very resistant to fading. The printing process creates a durable image. However, you should keep your standee out of direct, prolonged sunlight. This helps preserve the colors and the material for many years.

See Also

Exploring Premium Acrylic Stand Tables: Design, Materials, and Craftsmanship Explained

Your Comprehensive Guide to Selecting the Perfect Acrylic Table Stands

Innovative Uses for Acrylic Table Top Stands in Retail Showcases

Understanding Acrylic Sign Holders: Defining Features and Practical Applications

Acrylic Watch Displays: Defining Their Structure and Diverse Applications