Modern acrylic standees durable design is a result of specific advancements. The durability of these acrylic stands comes from the type of acrylic used and innovative printing methods. This improved durability also stems from protective coatings and smart structural choices for the acrylic stands.

These elements are the definitive answer to why today’s acrylic stands resist common issues. Problems like scratches, UV fading, and breaking are no longer major concerns for quality acrylic stands.

Why Material Choice Makes Acrylic Standees Durable

The foundation of a strong standee is the material itself. The choice of acrylic directly impacts its strength and lifespan. High-quality acrylic stands are not made from just any plastic; they use specific, advanced formulations designed for durability.

High-Density Cast Acrylic

Modern acrylic stands use a special material called high-density cast polymethyl methacrylate (PMMA). This material is very strong. It is made using a slower process that results in a higher molecular weight. This makes the acrylic stands very tough. Cast acrylic is stronger and more stress-resistant than cheaper extruded acrylic. It has greater resistance to cracking or chipping from accidental drops. This superior durability and safety make it ideal for collectibles.

The strength of cast PMMA is why it is trusted in many demanding applications. You can find it in aquarium windows, aircraft canopies, and medical devices. These applications require a material that is both clear and incredibly resilient. Using this same material for acrylic stands ensures they can withstand daily handling. The choice of material is the first step in making acrylic standees durable. The durability of these acrylic stands is a key feature for many applications. These applications demand both clarity and strength. Many industrial applications also rely on this material.

Integrated UV-Resistant Polymers

Sunlight can damage many materials over time. It can cause colors to fade and the material itself to become yellow and brittle. To fight this, modern acrylic stands have UV-resistant polymers blended directly into the material. This makes the acrylic a truly weather-resistant material.

These polymers are made from specific monomers that are naturally resistant to ultraviolet light. Some common examples include:

- Methyl methacrylate

- Butyl acrylate

- 2-ethylhexyl acrylate

This built-in weather resistance ensures the long-term durability of your acrylic stands. It protects both the artwork and the structural integrity of the acrylic.

The benefit is clear. This UV protection prevents discoloration and keeps the standee looking new. It stops colors from fading, even with exposure to sunlight. This maintains the visual appeal of the acrylic stands for years to come.

Advanced Manufacturing for Custom Acrylic Standees

The material is only half the story. Modern manufacturing methods turn high-quality acrylic into finished products. These techniques are crucial for the durability of custom acrylic standees. They protect the artwork and strengthen the structure of the acrylic stands. Advanced processes ensure the final custom acrylic standees are both beautiful and resilient. This manufacturing excellence makes acrylic standees durable.

Sub-Surface Printing for Scratch-Proof Art

The artwork on custom acrylic standees needs protection. Traditional surface printing leaves the image exposed to scratches, chipping, and fading. Advanced manufacturing for custom acrylic standees solves this with sub-surface printing.

This method, also known as second-surface printing, prints the design on the back of the clear acrylic. The image is then viewed through the front of the acrylic stands.

This technique places the acrylic material itself as a protective barrier. The artwork is permanently sealed behind the acrylic, making it virtually scratch-proof from the front. This process is essential for the long-term durability of the design. It ensures your customizable acrylic displays remain vibrant. The customizability of these acrylic stands does not compromise their strength. This method protects the art on all kinds of custom acrylic standees.

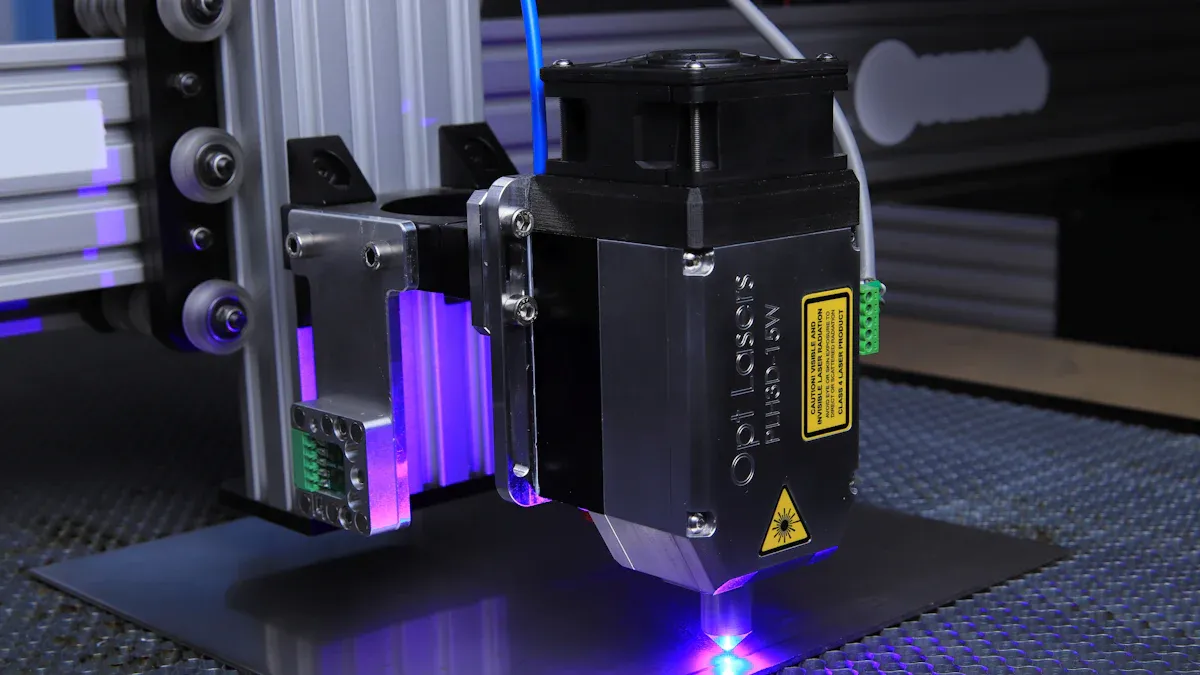

Precision Laser-Cut Polished Edges

The edges of acrylic stands are potential weak points. Poorly cut edges can have micro-fractures that lead to chipping or cracking. Professional manufacturers use advanced CNC laser cutters for their custom acrylic standees. This technology offers incredible precision. It cuts the acrylic stands with a tolerance as fine as 0.1mm. This accuracy creates a smooth, clean edge that is free from stress points.

The laser melts the acrylic as it cuts. This process naturally flame-polishes the edge, giving it a glossy, transparent finish. Some high-end customizable acrylic displays even receive a diamond polish. This enhances the three-dimensional look and creates truly eye-catching displays. The smooth, sealed edge from precision cutting improves the overall durability of the custom acrylic standees. It prevents weak spots from forming, ensuring the acrylic stands can resist damage. These high-quality edges are a hallmark of premium customizable acrylic displays and custom acrylic standees.

Protective Finishes and Structural Design

Excellent materials and manufacturing are not the final steps. Smart design choices and protective finishes add the last layers of strength. These features ensure the final acrylic stands are robust and long-lasting.

Anti-Scratch and Oleophobic Coatings

Even the toughest acrylic can get smudged. High-quality acrylic stands often feature specialized top coatings for added protection. An anti-scratch clear coat provides a hardened surface. An oleophobic coating offers another key benefit.

This type of coating uses a nano-film to actively repel oils from fingerprints. Instead of smearing, oils bead up on the surface. This makes the acrylic stands incredibly easy to wipe clean. A high-quality coating will have a contact angle of over 105°, showing its strong oil-repelling power. This technology keeps your acrylic stands looking clean and new.

The Role of Thickness and Epoxy Doming

The physical thickness of acrylic stands directly impacts their strength. While a 3mm thickness is common, upgrading to a 4.5mm or 5mm thickness provides a major boost in rigidity. Thicker acrylic stands are much more resistant to bending or snapping from accidental drops. This increased durability makes them a better long-term investment.

For ultimate protection, some acrylic stands feature an epoxy dome. This is a thick, clear layer of resin applied over the artwork side. It creates a smooth, rounded bubble that offers several advantages:

- Adds another thick, protective barrier against impact.

- Magnifies the artwork slightly for a premium look.

- Seals the design completely from moisture and wear.

Reinforced Bases for Sturdy Acrylic Stands

A standee is only as strong as its weakest point. The base and connection tab are critical for stability. Well-designed acrylic stands use reinforced bases to prevent wobbling and reduce stress. Key design principles include:

- Wider Footprints: A larger base provides a more stable foundation.

- Precise Connections: A snug tab-and-slot fit prevents the standee from leaning or falling out.

- Appropriate Thickness: The base itself is made from thick material to support the main piece without bending.

This thoughtful engineering is what makes acrylic standees durable. It ensures the acrylic stands remain upright and stable on your shelf. The overall durability of the acrylic stands depends heavily on this structural integrity.

Proper Care to Maximize Lifespan

Even the most durable products benefit from proper care. Following simple maintenance guidelines will ensure your acrylic stands remain in pristine condition for years. Correct cleaning and safe storage are essential to maximizing the lifespan of your collection of acrylic stands.

Correct Cleaning and Polishing

Cleaning your acrylic stands correctly prevents scratches and damage. Always use a soft, non-abrasive microfiber cloth. Paper towels or rough fabrics can create tiny scratches on the surface. For general dusting, a dry microfiber cloth is sufficient.

For a deeper clean, use a simple and safe solution.

- Mix a few drops of mild dish soap with lukewarm water.

- Dampen your microfiber cloth with the solution.

- Gently wipe the acrylic stands without applying heavy pressure.

- Use a separate, dry microfiber cloth to pat the surface dry and prevent water spots.

It is critical to avoid harsh chemicals. Many common household cleaners can permanently damage your acrylic stands. Never use products containing ammonia, acetone, gasoline, or other solvents. These chemicals can cause the material to become cloudy or brittle. Sticking to soap and water is the safest way to clean your acrylic stands.

Safe Handling and Storage

Proper handling prevents accidental drops and chips. When moving your acrylic stands, hold them by the base and the main body. This provides better support than holding them by a thin or delicate part. Careful handling is the first step in protecting your acrylic stands.

Safe storage is equally important for long-term preservation. If you need to store your acrylic stands, wrap each piece individually in bubble wrap or a soft cloth. Place them in a sturdy box with padding to prevent them from shifting. This protects the acrylic stands from scratches and impact.

The storage environment also matters. Keep your acrylic stands in a cool, dry place with a stable temperature, ideally between 60-80°F (16-27°C). Avoid areas with high humidity or direct sunlight, as these conditions can cause warping or fading over time. A controlled environment is best for all your acrylic stands.

The durability of modern acrylic stands comes from several key factors. These include superior materials, protected printing, and intelligent design for all acrylic stands. These combined elements make acrylic standees durable. The durability of these acrylic stands ensures your acrylic stands are a lasting investment. Your acrylic stands will remain strong.

Proper selection and care guarantee the quality of your acrylic stands. These acrylic stands, your acrylic stands, and all quality acrylic stands will look great for many years.

FAQ

What makes cast acrylic better for standees?

Cast acrylic is stronger than other plastics. Its high-density structure resists shattering and impact. This strength is essential for many demanding applications. The material’s resilience makes it perfect for collectible applications and long-term use. These applications require a durable product.

How thick should my standee be?

Thickness depends on its use. A 3mm standee works for many applications. A 4.5mm or 5mm standee offers more rigidity for larger or high-use applications. This thicker display solution is better for public-facing applications. The applications of acrylic stands often determine the best thickness.

Can I use window cleaner on my acrylic standee?

No. Never use cleaners with ammonia or harsh solvents. These chemicals damage the acrylic. Stick to mild soap and water with a soft microfiber cloth. This simple method is safe for all applications and keeps your display solution looking new.

Why are modern standees so much stronger?

Modern standees use better materials and manufacturing. Cast PMMA, sub-surface printing, and reinforced bases create a superior product. These improvements support a wide range of applications. The applications of acrylic stands have expanded due to this increased durability. Many new applications are now possible.

See Also

Your Comprehensive Guide to Acrylic Table Stands and Displays

Exploring Premium Acrylic Stand Tables: Design, Materials, and Craftsmanship

Innovative Display Ideas: Utilizing Acrylic Table Top Stands for Showcases

Acrylic Sign Holders: Understanding Their Definition, Features, and Uses

Elevate Your Tabletop: Stylish Organization with Large Acrylic Trays