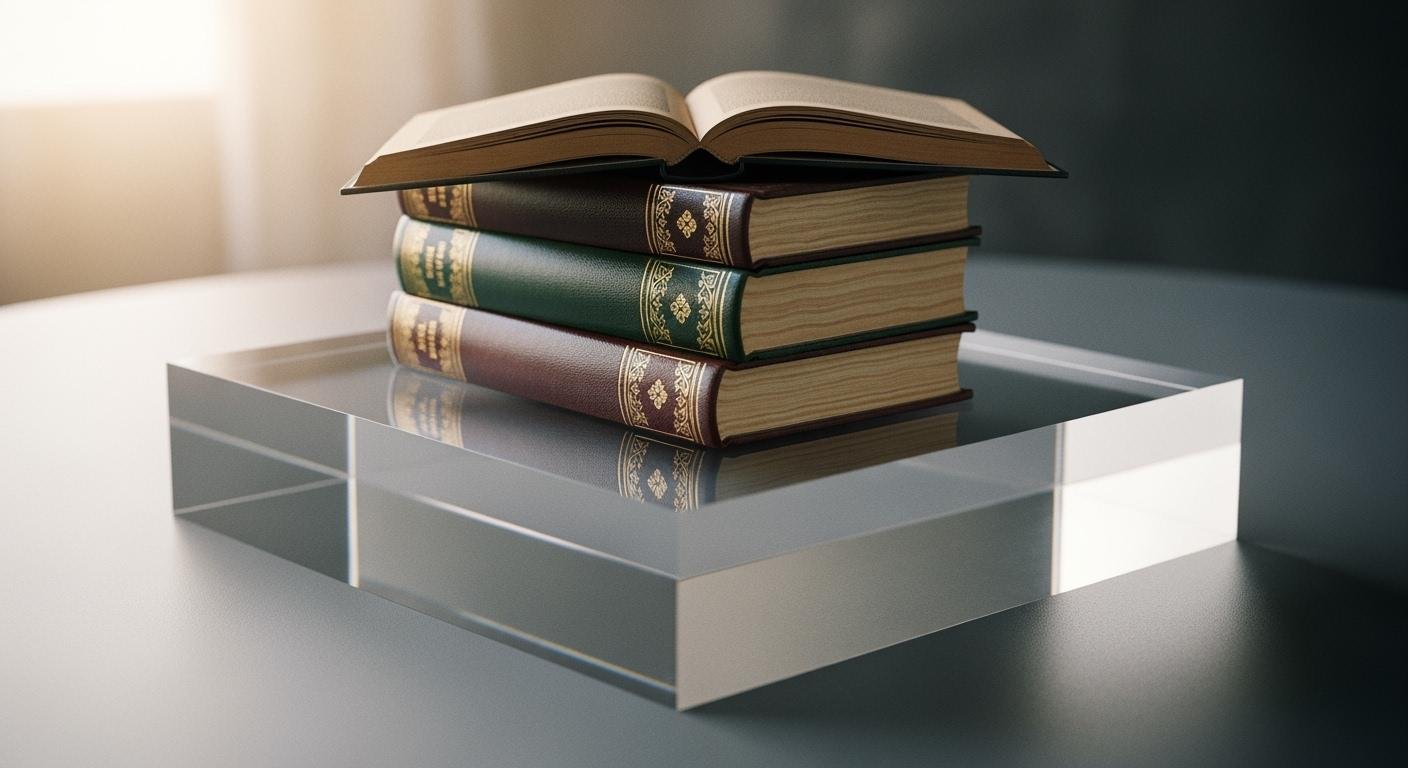

For applications demanding exceptional strength and durability, acrylic blocks are a top choice over traditional materials. Acrylic is a highly impact resistant material. This quality makes acrylic ideal for high impact applications. The versatility of acrylic also suits many other applications.

The unique combination of features in acrylic makes it a smart and reliable investment.

The Superior Strength of Acrylic

The primary advantage of acrylic is its remarkable strength. This material provides a level of resilience that traditional glass and even other plastics cannot match. Its unique properties make it a superior choice for demanding applications.

Impact Resistance vs. Glass

Acrylic demonstrates a significant advantage in impact resistance over glass. In fact, acrylic has roughly 17 times more impact strength than standard glass of the same thickness. This makes the material an excellent choice for safety and security applications. The following table shows the results of a falling ball impact test on different materials.

| Material | Falling Ball Impact Strength (ft-lbs) |

|---|---|

| 0.250″ Thick Plate Glass | 1.0 |

| 0.250″ Thick Tempered Glass | 15.5-29.1 |

| 0.250″ Acrylic Sheet | 18.1 |

Beyond its raw strength, acrylic offers a crucial safety benefit in how it breaks. Glass shatters into dangerous, sharp shards. Acrylic, on the other hand, is virtually shatter-resistant. If it does fracture under extreme force, it breaks into large, dull-edged pieces. This safer fracture pattern minimizes the risk of injury.

Many acrylic products hold official safety ratings. For example, certain acrylic sheets meet the strict requirements for Florida’s High Velocity Hurricane Zones. Specialized bullet-resistant acrylic is also certified under UL 752 standards for protection.

Finally, acrylic provides this superior strength at half the weight of glass. This impressive strength-to-weight ratio makes handling and installation much easier without sacrificing durability.

Strength vs. Other Plastics

Acrylic also stands out when compared to other common plastics. Its tensile strength, which measures a material’s resistance to being pulled apart, is a key indicator of its durability. The tensile strength of acrylic is approximately 9,500 psi. This is significantly higher than the tensile strength of both PVC and polycarbonate.

Professionals measure the properties of plastics using standardized tests. The ASTM D638 standard, for instance, is a common method used to determine the tensile strength of plastics. These tests confirm that acrylic is a robust and reliable material. The inherent strength of acrylic makes it a top performer for applications requiring a rigid, impact resistant, and durable plastic. The strong acrylic blocks are a testament to the material’s engineering excellence.

The Long-Term Durability of Acrylic

Strength is only one part of the equation. A material must also withstand the test of time. The long-term durability of acrylic ensures it remains a reliable and visually appealing choice for years. This durability comes from its resistance to environmental factors, surface wear, and chemical exposure.

UV and Weather Resistance

A common concern with plastics is their tendency to yellow when exposed to sunlight. However, modern acrylic formulations solve this problem effectively. Manufacturers add UV stabilizers to the material during production. These stabilizers protect the acrylic from solar radiation and prevent discoloration. This protection gives the material exceptional durability for outdoor use.

Many high-quality acrylic products are guaranteed to resist yellowing for extended periods.

- Outdoor-grade acrylic with UV stabilizers can maintain its clarity for over 10 years.

- Some premium brands, like Perspex®, even offer a 30-year guarantee against yellowing on their clear cast sheets.

This performance makes acrylic a superior choice compared to other plastics like standard polycarbonate, which can yellow more quickly without special UV-resistant coatings. The weather resistance of acrylic is verified through standardized testing. Professionals use methods like ASTM G155 and ASTM D4329 to simulate long-term outdoor exposure and confirm the material’s lasting durability.

Scratch and Surface Wear

The surface of acrylic is softer than glass. It has a Mohs hardness rating between 3 and 4, similar to a copper penny. This means it can be more susceptible to scratches in high-traffic environments. However, the overall durability of acrylic remains high due to its unique repairability. Unlike glass, which cannot be polished, minor scratches on an acrylic surface can be easily buffed out.

The following table compares the surface wear of acrylic and glass in a typical retail setting.

| Fonctionnalité | Glass (Tempered) | Acrylique |

|---|---|---|

| Résistance aux rayures | Resists scratches well. | Scratches more easily than glass. |

| Scratch Repair | Cannot be polished or repaired. | Scratches can be polished away. |

| Maintenance | Easier to clean with standard products. | Requires special cleaners to avoid damage. |

| Durability in High-Traffic | Excels and requires fewer replacements. | Scratches can affect appearance over time. |

Tip: How to Repair Scratches on Acrylic

One of the greatest benefits of acrylic is its forgiving surface. Light scratches can be removed with a simple process.

- For deep scratches that catch a fingernail, start with wet 600 grit sandpaper. Rub the area in a circular motion.

- Progress to finer grits, like 800 and then 1200 grit sandpaper, until the scratch is no longer visible.

- Finish by applying a dedicated acrylic polish with a soft, clean cotton cloth to restore the surface’s original shine.

Chemical and Temperature Stability

The excellent durability of acrylic extends to its chemical and thermal properties. The material maintains its structural integrity across a wide range of temperatures. Cast acrylic has a continuous service temperature from -40°F to 180°F, making it suitable for both indoor and outdoor applications in various climates.

It is important to account for thermal expansion in large installations. Acrylic expands and contracts with temperature changes.

For large sheets, installers should use channel frames that allow the material to move freely. This prevents bowing and ensures the long-term stability of the installation.

Furthermore, acrylic offers high resistance to many common chemicals. This property makes it a valuable material in industrial, laboratory, and commercial settings. It is generally unaffected by alkalis, detergents, and dilute inorganic acids. The table below lists some of the specific chemicals that acrylic can withstand.

| Chemical Category | Examples of Resistant Chemicals |

|---|---|

| Building Materials | Cement, Mortar, Plaster of Paris |

| Acids (Diluted) | Acetic acid (5%), Hydrochloric acid, Citric acid (20%) |

| Solvents & Alcohols | Heptane, Hexane, Glycerol, Ethyl alcohol (to 15%) |

| Salts & Other Chemicals | Calcium chloride, Copper sulphate, Ammonia (aqueous) |

This robust chemical resistance, combined with its thermal stability, solidifies the position of acrylic as a material with superior durability for demanding projects.

Practical Benefits of Acrylic Blocks

Beyond strength and durability, acrylic offers significant practical advantages. These benefits make it easier and more cost-effective to use in a wide range of projects. Its lightweight nature and design flexibility are key reasons professionals choose this modern material.

Lightweight and Easy Handling

One of the most notable benefits of acrylic is its low weight. It is approximately half the weight of glass, which dramatically simplifies handling and installation. This weight difference reduces the need for heavy machinery and large work crews, leading to lower labor costs. The following table compares the weight of similarly sized acrylic and glass blocks.

| Material | Dimensions (in.) | Weight (lb.) |

|---|---|---|

| Acrylique | 8 x 8 x 2 | 1 |

| Verre | 8 x 8 x 4 | 6 |

This reduced weight also translates into significant savings on shipping. Lighter materials cost less to transport, making large-scale projects more economical. Furthermore, the lightweight nature of acrylic means it requires less robust structural support than glass. This is a major advantage in large architectural applications, where it can reduce the complexity and cost of the underlying frame.

Fabrication and Design Freedom

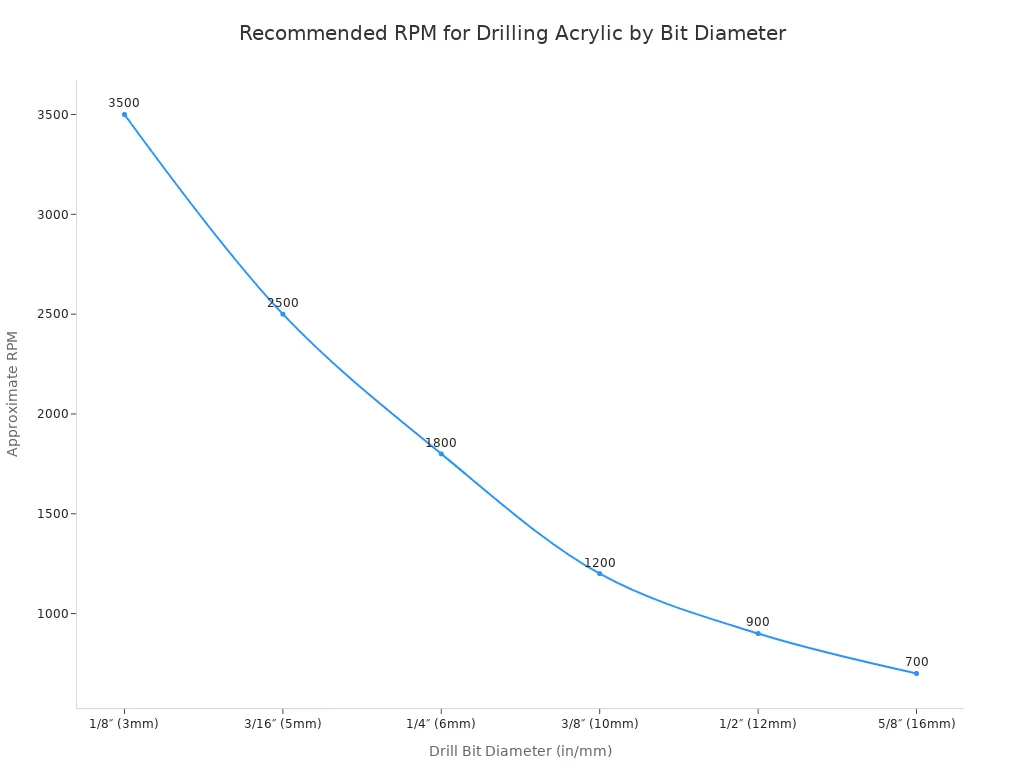

Acrylic provides unmatched freedom for designers and fabricators. The material can be easily cut, drilled, bonded, and polished. This workability allows for the creation of intricate shapes and custom designs that are difficult to achieve with glass. For example, drilling acrylic requires specific speeds for clean results.

The versatility of acrylic extends to thermoforming. This process involves heating a sheet until it becomes pliable and then molding it into a custom 3D shape.

This capability opens the door for innovative designs. Architects have used the flexibility of acrylic blocks and sheets in famous structures.

- The Eden Project in the UK uses acrylic bio-domes.

- The Louvre Pyramid in Paris features lightweight acrylic panels.

These examples show how the material’s properties enable creative and functional applications.

Acrylic blocks deliver a powerful combination of benefits that make them a superior choice. The material’s performance comes down to three key areas:

- Superior Strength: Acrylic is highly impact resistant and far stronger than glass.

- Long-Term Durability: Modern acrylic resists yellowing and weathering, ensuring lasting clarity and durability.

- Practical Advantages: The lightweight nature of acrylic simplifies handling, while its easy fabrication allows for design freedom.

This blend of strength and reliability confirms acrylic is a modern, cost-effective solution. For projects where clarity and performance are essential, strong acrylic blocks are the smart investment.

FAQ

Is acrylic more expensive than glass?

Acrylic can have a higher initial cost than standard glass. However, its lower weight reduces shipping and installation expenses. This often makes the total project cost comparable or even lower. Its durability also means fewer replacements over time, offering long-term value.

How do you clean acrylic blocks?

Proper cleaning maintains the block’s clarity. Use a soft cloth with mild soap and water.

Important: Avoid using harsh chemicals like ammonia or abrasive cleaners. These products can damage the surface and cause cloudiness. Always pat the surface dry to prevent water spots.

Is acrylic the same as polycarbonate?

No, they are different materials. Polycarbonate offers higher impact strength. However, acrylic sheeting has better optical clarity and is more resistant to scratches. Acrylic is also generally more affordable and easier to polish than polycarbonate, making it a popular choice.

Can you use acrylic blocks outside?

Yes, acrylic is excellent for outdoor use. Modern clear acrylic sheeting contains UV stabilizers. These additives prevent the material from turning yellow in the sun. This protection ensures the blocks maintain their strength and transparency for many years in various weather conditions.

See Also

Exploring Acrylic Blocks: Understanding Their Definition, Uses, and Characteristics

Choosing and Caring for White Acrylic Trays: A Comprehensive Guide

Your Essential Handbook to Selecting the Perfect Acrylic Table Stands

Discovering Impact-Modified Acrylic: Its Nature, Attributes, and Practical Uses