Your business can enhance its presentation with durable acrylic trays. Buying clear acrylic trays wholesale is a smart financial move. This wholesale approach helps manage costs for your trays.

注: The wholesale process for wholesale acrylic trays can seem complex. This guide simplifies your acrylic trays wholesale purchase. You will learn to vet a supplier for your wholesale retail acrylic trays. Secure the best wholesale deal for your acrylic trays.

Key Factors for Buying Clear Acrylic Trays

You must evaluate several key factors before placing a wholesale order. This ensures you receive products that meet your quality standards and business needs. Making the right choices in material, design, and customization will lead to a successful purchase. This part of the guide covers the critical details for buying clear acrylic trays.

Material Quality: Cast vs. Extruded Acrylic

The type of acrylic you choose directly impacts the tray’s appearance, durability, and cost. You will primarily choose between two types: cast and extruded acrylic. Cast acrylic offers superior clarity and strength. Extruded acrylic is a more budget-friendly option.

| 特徴 | キャストアクリル | 押出アクリル |

|---|---|---|

| クラリティ | Exceptional optical clarity and transparency, like glass. | Very good clarity, but slightly less than cast. |

| 耐久性 | Higher impact resistance and less prone to scratching. | Good durability but lower impact resistance. |

| Machining | Easier to machine, cut, and polish for a clean finish. | Can be more prone to melting or chipping during fabrication. |

| Chemical Resistance | More resistant to solvents and chemicals. | Less resistant to harsh cleaning agents. |

For wholesale orders, you should know that cast acrylic typically costs 15-25% more than extruded acrylic. The manufacturing process for cast acrylic is more labor-intensive. It involves pouring liquid resin into molds, which creates a more uniform and durable material. This process results in superior optical quality and makes the acrylic easier to machine. Extruded acrylic is made by forcing melted pellets through a die. This method is faster and cheaper, but the final product can have minor imperfections and is slightly less durable. Your choice depends on balancing your budget with the need for high-quality acrylic.

Dimensions, Capacity, and Intended Use

You need to define the exact purpose of your trays. This will determine the right size, shape, and thickness. Consider what you will place on the trays. Will they hold heavy glassware, delicate pastries, or retail products?

- Thickness: For most commercial uses, a thickness of 4-5mm is ideal. This provides excellent durability and a substantial feel without being too heavy. Thinner acrylic might be cheaper but can crack or bow under weight.

- Size and Shape: Measure the items the trays will carry. Ensure there is enough space for easy handling. For wholesale retail acrylic displays, the dimensions should complement your products, not overwhelm them.

- Load Capacity: Ask potential suppliers about the weight capacity of their trays. A well-made tray should handle its intended load without any bending.

Thinking about these details helps you avoid problems later. A tray that is too small or weak will not serve your business well.

Essential Design and Functionality Features

Good design combines looks with practical use. When buying clear acrylic trays, look for features that improve both safety and style. These details create premium acrylic trays that impress customers.

Pro Tip: Always check for polished edges. Raw, unpolished edges can be sharp and look unfinished. Polished edges are smooth to the touch, safe for handling, and give the acrylic a professional, glass-like finish.

Other important features include:

- Custom Sizing: You can order trays with exact dimensions for a perfect fit in your space.

- Color Options: While clear is popular, you can also find trays in white, black, or other custom colors.

- Handles or Grips: Cut-out handles make the trays easier and safer to carry, especially in a busy environment.

- Easy-to-clean trays: A non-porous, smooth surface is crucial for hygiene and quick cleanup.

If you plan to serve food or drinks, your trays must have a food-grade certification. This is a non-negotiable safety requirement. Regulations vary by region, so confirm your supplier meets the standards for your market.

| Country/Region | Regulations | Key Requirements |

|---|---|---|

| European Union (EU) | Regulation (EC) No 1935/2004, Regulation (EU) No 10/2011 | Materials must not release harmful substances. Plastics must meet specific migration limits (OML/SML). |

| United States (US) | 21 CFR Parts 174 – 178 | Materials must comply with FDA rules for food contact substances, including migration data and authorized use. |

Sourcing Wholesale Custom Acrylic Trays

One of the biggest advantages of buying wholesale is the ability to get custom acrylic trays. Customization transforms a simple tray into a powerful branding tool. You can create custom acrylic trays with creative design elements that reflect your brand’s identity. When you order in bulk, many suppliers offer extensive customization options.

Popular choices for wholesale custom acrylic trays include:

- Logo Printing: Add your company logo using different printing methods.

UV printingcreates vibrant, full-color designs.Silkscreen printingis cost-effective for simpler, one or two-color logos on a large bulk order.

- Laser Engraving: For a subtle and elegant look, you can have your logo or a design engraved into the acrylic. This creates a permanent, high-end finish.

Discuss these customization options with your supplier to see what they can offer. A custom design makes your trays unique and reinforces your brand.

Evaluating a Supplier’s Manufacturing Process

The quality of your trays depends on the manufacturer’s process. A reliable supplier will have strict quality control measures. When you order wholesale, you should ask about their manufacturing standards.

A good manufacturer adheres to tight precision tolerances, often around ±0.1mm, to ensure every tray is perfectly made. They should also perform several quality checks. Ask if their process includes tests like these:

- Tilt Test: Items should not slide off the tray when it is tilted at a 7-degree angle.

- Drop Test: The tray should not crack or deform when dropped from a low height (e.g., 20cm).

- Adhesion Test: Any printed or engraved designs should not flake or peel when scratched.

- Wipe Test: A damp cloth should not leave streaks or damage the finish.

- Smell Test: A fully cured acrylic tray should have no chemical odor.

Understanding these steps helps you vet a supplier. It ensures you receive consistent, high-quality custom acrylic trays with every wholesale order.

Finding the Right Wholesale Manufacturer

Choosing the right partner is the most important step in sourcing acrylic trays in bulk. A great manufacturer ensures quality products and a smooth process. A poor one can cause delays and deliver subpar trays. This section guides you through finding and vetting the perfect acrylic tray supplier for your wholesale needs.

Sourcing Channels: Direct vs. B2B Platforms

You have two main paths for finding a wholesale supplier: working directly with a factory or using wholesale b2b platforms like Alibaba. Each channel has its own advantages and disadvantages. Your choice will depend on your budget, customization needs, and experience with importing.

Working direct from manufacturer often gives you better pricing and more control over customization. You communicate straight with the people making your acrylic trays. This is a great option if you need specific OEM or ODM services. However, it requires more effort on your part.

B2B platforms offer a huge selection of suppliers in one place. You can easily compare prices and options. This convenience can come with risks, like inconsistent quality and communication challenges.

Here is a comparison to help you decide:

| Sourcing Method | 長所 | 短所 |

|---|---|---|

| Direct from Manufacturer | Customization, factory pricing, reliable quality | Slightly longer lead times (15–30 days), requires importing knowledge |

| B2B Platforms (e.g., Alibaba) | Many supplier options, price comparison | Quality inconsistency, potential communication barriers |

Key Questions for Vetting Suppliers

Once you have a shortlist of potential suppliers, you need to vet them carefully. Asking the right questions helps you avoid problems later. A professional supplier will be happy to provide detailed answers.

Key Tip: Don’t just focus on price. A reliable partner who delivers quality trays on time is more valuable than the cheapest option.

Here are some essential questions to ask a potential supplier:

- Certifications: Do you have quality management certifications like

ISO 9001? This shows the factory follows strict standards for consistent quality. - Experience: How long have you been manufacturing acrylic products? Can you provide examples of similar trays you have made?

- Customization (OEM/ODM): What are your capabilities for custom designs, logos, and colors? Can you work from our design files?

- Material Sourcing: Where do you source your acrylic material? Do you offer both cast and extruded acrylic?

- After-Sales Service: What is your process for handling defects or issues with an order? A good partner will have a clear policy for replacements or refunds.

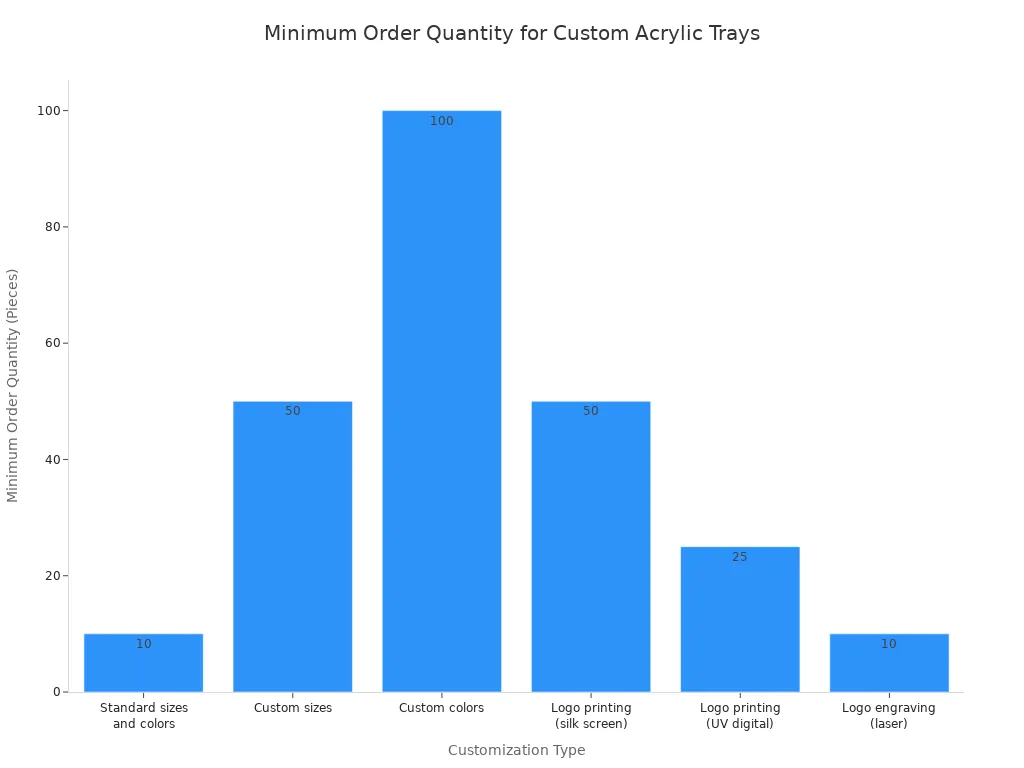

Understanding MOQ and Production Lead Times

Before you commit to a wholesale order, you must understand two key terms: Minimum Order Quantity (MOQ) and production lead time.

MOQ is the smallest number of units you can order. This number often changes based on customization. A factory has lower MOQs for standard trays and higher MOQs for custom colors or complex designs.

Here are some typical MOQs for custom acrylic trays:

| Customization Type | Minimum Order Quantity (MOQ) |

|---|---|

| Standard sizes and colors | 10 pieces |

| Custom sizes | 50 pieces |

| Custom colors | 100 pieces |

| Logo printing (silk screen) | 50 pieces |

| Logo printing (UV digital) | 25 pieces |

| Logo engraving (laser) | 10 pieces |

Production lead time is the time it takes the factory to make your trays, from design approval to final packaging. For a large wholesale order of 1,000 units, you can expect a lead time of 4-6 weeks. This includes steps like prototyping, material sourcing, fabrication, and quality inspection. Always confirm the timeline with your manufacturer and plan for potential delays.

Assessing Quality Control and Packaging

A manufacturer’s commitment to quality does not end when the trays are made. You need to assess their quality control (QC) and packaging processes. Poor packaging can ruin a perfect product.

Ask about their QC checks. Do they inspect each tray for scratches, bubbles, and sharp edges? A factory with ISO 9001 certification has proven its commitment to a quality management system.

Packaging is especially important for fragile acrylic products. A seller who shipped 200 keychains to the U.S. without proper reinforcement lost over $180 from 37 damaged units. Your trays need protection.

Look for a supplier who uses these best practices:

- Surface Protection: Each tray should be covered in a protective film to prevent scratches.

- Edge Reinforcement: EPE foam strips or cardboard corners should protect the edges and corners of the trays.

- Sturdy Boxing: The trays should be packed in strong, double-wall corrugated boxes that can pass a drop test.

- Clear Labeling: Boxes must be clearly marked as “Fragile” to ensure careful handling during shipping.

The Benefits of Working Directly with a Manufacturer

While b2b platforms are useful for research, building a relationship for factory direct purchasing offers significant long-term benefits. When you work directly with a factory, you gain a partner invested in your success.

The main advantages include:

- Better Pricing: You eliminate middlemen, which lowers your cost per unit on bulk orders.

- Greater Control: You have direct input on design, materials, and quality for your acrylic trays. This is ideal for complex OEM projects.

- Stronger Relationships: Direct communication builds trust and makes it easier to resolve issues.

- Reliable Quality: A dedicated factory partner will understand your standards and consistently deliver high-quality acrylic products.

Finding the right wholesale partner takes time, but the effort pays off. A great manufacturer will help you create beautiful, durable trays that elevate your brand.

Optimizing Your Wholesale Order for Value

You can make your wholesale purchase more profitable with smart planning. Optimizing your order involves more than just finding a low price. You must balance quantity, design, and shipping to get the best return on your investment. This section shows you how to maximize the value of your custom acrylic trays.

Ordering in Bulk to Maximize Value

Ordering in bulk is a fundamental strategy for wholesale buying. Manufacturers offer better pricing on larger orders because it makes their production more efficient. You will see significant price breaks as your order quantity increases. This directly lowers your cost per tray.

| Quantity | Price Per Item |

|---|---|

| 1-23 | $5.09 |

| 24+ | $4.25 |

Buying your acrylic trays in bulk also reduces your per-unit shipping cost. You can get discounts from 15% to 45% on wholesale orders over 1,000 units. This makes large-scale purchases of trays very cost-effective.

Balancing Cost with Design Complexity

Your design choices directly affect the final cost of your custom acrylic trays. Simple, standard trays are more affordable. Complex shapes, thick acrylic, or intricate custom features will increase the price. You must balance your creative vision with your budget to achieve competitive pricing. The material you choose is a major cost factor.

| 素材タイプ | Cost-Effectiveness | Characteristics |

|---|---|---|

| 押出アクリル | More cost-effective for large-scale production, good for price-sensitive buyers | Slightly less clear than cast, more prone to scratching, durable enough for everyday uses |

| キャストアクリル | More expensive, worth the investment for high-end markets | Clearer, more scratch-resistant, more durable, cuts and engraves cleanly for intricate designs |

Profit-Boosting Options like Custom Inserts

Smart Tip: You can transform your trays from simple containers into powerful marketing tools. Consider using custom acrylic trays with inserts to enhance customer experience and drive sales.

Many successful brands use custom acrylic trays with inserts to connect with customers. For example, beauty brands like Glossier and Birchbox used custom acrylic trays with inserts to include thank-you notes or upsell offers. These custom acrylic trays with inserts helped them increase engagement and convert sales. You can use custom acrylic trays with inserts for your wholesale retail acrylic business. These custom acrylic trays with inserts can hold referral cards, just as Dollar Shave Club did to grow its customer base. Using custom acrylic trays with inserts is a smart way to add value. These custom acrylic trays with inserts make your packaging memorable. Think about how custom acrylic trays with inserts can boost your brand.

Navigating Shipping: FOB vs. DDP Terms

Understanding shipping terms is crucial for managing your wholesale budget. Two common terms are FOB (Free On Board) and DDP (Delivered Duty Paid). With FOB, your responsibility as the buyer begins once the trays are loaded onto the shipping vessel. You must handle the rest.

Your key responsibilities under FOB terms include:

- Designating the carrier and arranging the transport contract.

- Paying for freight charges to the destination.

- Handling all import customs formalities, duties, and taxes.

- Assuming risk for the acrylic trays once they are on the vessel.

Choosing the right shipping terms for your wholesale order helps you control costs and logistics for your custom trays.

You now have a clear path for buying clear acrylic trays wholesale. Your successful wholesale purchase follows three key steps. First, you must define your ideal acrylic trays. Second, you should vet suppliers for your wholesale acrylic order. Third, you need to optimize your wholesale logistics for the best value on your acrylic trays.

Bookmark this guide. 📝 Use it as your checklist for your next wholesale purchase of acrylic trays. You can now source high-quality trays with confidence, making buying clear acrylic trays a smart process.

よくあるご質問

What is the best acrylic for food service trays?

You should choose cast acrylic for food service trays. This material offers superior clarity and durability. Most importantly, you must ensure the acrylic trays have a food-grade certification. This guarantees the trays are safe for direct contact with food.

Can I order a sample before a bulk purchase?

Yes, you should always request a sample. Reputable manufacturers will provide a sample of their acrylic trays. This allows you to check the quality, finish, and durability. You can also see how your custom logo looks on the acrylic.

How do I clean and maintain my acrylic trays?

You can easily clean your acrylic trays. Use a soft microfiber cloth with mild soap and water. You should avoid harsh chemicals or abrasive cleaners. These can scratch or damage the acrylic surface. Proper care keeps your trays looking new.

What is a typical MOQ for custom acrylic trays?

The Minimum Order Quantity (MOQ) for custom acrylic trays varies. For simple custom sizes, the MOQ might be around 50 pieces. For trays with a custom color or complex logo printing, the MOQ could be 100 pieces or more.

See Also

Choosing and Caring for Your White Acrylic Trays

Exploring Round Acrylic Tray Designs and Their Everyday Utility

Decorating Modern Homes with Elegant Clear Acrylic Trays

Organize Your Tabletop with Large, Stylish Acrylic Trays

Small Acrylic Trays: Your Versatile Solution for Storage Needs