Is a disadvantage of acrylic a dealbreaker? The answer depends entirely on your project. The material’s disadvantages can be manageable, but sometimes they are not.

Key issues with acrylic involve its physical durability, environmental impact, and overall cost. Understanding these points helps you weigh the pros and cons for your specific needs. You can then decide if acrylic is the right choice. This framework will help you make a confident decision.

The Main Disadvantage of Acrylic: Physical Durability

The primary disadvantage of acrylic is its physical durability. While strong in some ways, its weaknesses can be significant. Understanding these limitations is crucial before choosing acrylic for your project.

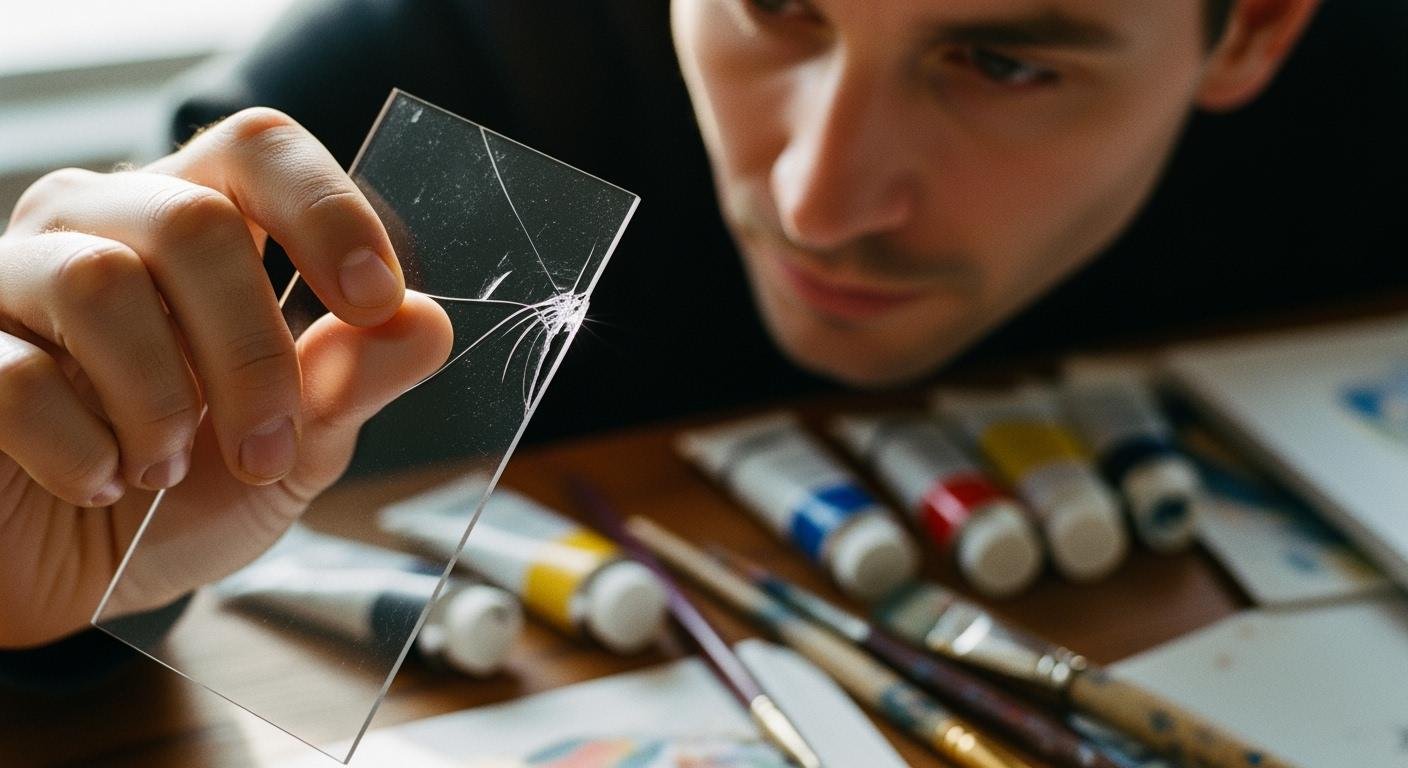

Scratch and Abrasion Resistance

Acrylic, also known as polymethyl methacrylate (PMMA), has a relatively soft surface. This softness leads to a high scratch susceptibility. Everyday objects sliding across an acrylic sheet can easily leave marks. This is a major difference compared to glass, which is much harder. The scratch susceptibility of PMMA is one of its most noted disadvantages.

Material Hardness Comparison The Mohs hardness scale shows how materials resist scratching. A higher number means better resistance.

Материал Mohs Hardness Rating Acrylic (PMMA) 3.5–4.0 Polycarbonate 2.5–3.0

Heat Sensitivity and Cracking

Acrylic is not very resistant to heat. Standard cast acrylic sheets can begin to deform at temperatures around 190°F (88°C). You should never place hot items directly on an acrylic surface. The material also has a potential for cracking under high stress. Its tensile strength is good, but it is a brittle plastic. This means a sharp impact or high pressure can cause cracking, sometimes resulting in hazardous sharp edges.

When Durability Is a Dealbreaker

In some situations, the physical limits of acrylic are absolute dealbreakers.

- High-Traffic Surfaces: A dining table or kitchen countertop made of acrylic would show wear very quickly.

- Safety Applications: While acrylic is shatter-resistant, its tendency to scratch can compromise visibility in protective barriers. Regulations often limit its use in safety glazing where pristine clarity is essential.

For these uses, the durability disadvantage of acrylic makes it an unsuitable choice.

When It Is Manageable

The durability issues of acrylic are not always a problem. For many applications, they are quite manageable. Museum display cases, for example, are often made from acrylic to protect valuable artifacts at institutions like the Smithsonian. Here, its optical clarity is more important than its surface hardness.

You can manage the material’s weakness with proper care:

- Clean surfaces with a soft microfiber cloth and mild soap.

- Use acrylic-safe polishes to remove minor scratches.

- Place felt pads under objects to prevent sliding and scratching.

With the right maintenance, the benefits of acrylic can easily outweigh its drawbacks.

Environmental Impact and Sustainability

The environmental impact of acrylic is a growing concern for many consumers. As a plastic, its lifecycle from creation to disposal presents significant challenges. These issues can be major disadvantages depending on your project’s goals and your personal values.

Production and Disposal Concerns

The journey of acrylic, or polymethyl methacrylate, begins with fossil fuels. Its production is an energy-intensive process. This contributes to the material’s overall carbon footprint. The bigger issue, however, is what happens after its use.

A Recycling Reality Check ♻️ Acrylic is not widely recycled. Globally, only about 10% of post-consumer pmma waste is successfully recycled. This means the vast majority of old acrylic products end up in landfills, where they do not biodegrade.

This low recycling rate for pmma makes disposal a serious environmental problem.

When Environmental Impact Is a Dealbreaker

For certain applications, the environmental impact is a clear dealbreaker.

- Single-Use Items: Using acrylic for disposable products or short-term signage is highly wasteful.

- Eco-Conscious Projects: If your brand or project is built on sustainability, choosing a petroleum-based plastic with poor recyclability conflicts with that core value.

In these cases, the environmental drawbacks outweigh any benefits the material might offer.

When Its Longevity Is a Counterpoint

The story changes for long-term applications. A durable, long-lasting acrylic product can be more sustainable than a less durable alternative that needs frequent replacement. The longevity of acrylic can offset its initial environmental cost. An aquarium is a great example.

- A well-made acrylic tank can last a very long time. Its chemical welds create strong seams that are sometimes stronger than the panels themselves.

- Glass tanks have an average lifespan of 7 to 10 years, though some last longer.

- Choosing a high-quality pmma product that lasts for decades avoids the waste and resources needed to manufacture multiple replacements.

Here, the durability of acrylic turns a potential negative into a reasonable trade-off.

The Cost Factor: Acrylic vs. Alternatives

Cost is a significant factor when choosing materials. The price of acrylic can be a major disadvantage, especially when compared to glass. However, understanding the cost differences helps you see where its value lies.

A Price Comparison

Generally, acrylic sheets are more expensive than standard glass but often cheaper than polycarbonate. The price for pmma can change a lot based on thickness, quality, and special features. High-quality acrylic with UV protection or an abrasion-resistant coating is particularly expensive. These premium grades can cost over $50 per square foot, while standard sheets start much lower.

Cost Snapshot: 1/4-Inch Sheet Prices vary by supplier and location, but this gives a general idea.

Материал Approximate Cost per Sq. Ft. Laminated Glass $2.00 – $3.50 Standard Acrylic $3.50+

When the Cost Is a Dealbreaker

The higher price of acrylic is a dealbreaker for many projects.

- Large-Scale Applications: For projects needing many large panels, like standard office windows, the cost of acrylic adds up quickly. Glass is a more economical choice.

- Budget-Driven Projects: If you are on a strict budget, the premium for acrylic may not be affordable. Simple picture frames or tabletops that won’t see heavy use are examples where cheaper materials work just fine.

In these situations, the benefits of pmma do not outweigh its higher cost.

When the Premium Is Justified

Sometimes, the higher cost of acrylic is a smart investment. Its unique properties make it the best choice for certain jobs. As an alternative to glass, acrylic offers distinct advantages. For instance, an acrylic sheet weighs about half as much as a glass panel of the same size. This makes it perfect for:

- Large art installations

- Trade show displays

- Projects where structural support is limited

Furthermore, high-grade pmma offers superior optical clarity, transmitting up to 92% of visible light. This is even better than some types of high-clarity glass. This makes the material ideal for museum display cases and professional photography, where true color and detail are essential. Here, the shatter resistance and clarity of the acrylic justify its price.

Other Key Disadvantages to Consider

Beyond durability and cost, a few other disadvantages can influence your decision. The chemical makeup of acrylic makes it vulnerable to certain substances, and its appearance can change over time with sun exposure. Understanding these issues is key to choosing the right material.

Chemical Sensitivity and Staining

Acrylic has a notable susceptibility to certain chemicals. Harsh solvents like acetone, alcohol, and ammonia-based cleaners can cause the surface to craze, which looks like a network of fine cracks. This chemical sensitivity is a significant disadvantage of acrylic in environments where cleaning agents are common. The material, also known as pmma, can be permanently damaged by the wrong cleaning product.

A Note on Protection 🛡️ While standard acrylic is sensitive, advanced formulations and coatings can improve its resistance. Some modern resins, like certain waterborne DTM (Direct-to-Metal) products, show excellent performance against chemicals.

Protective coatings can also create a barrier.

- Fluoropolymer coatings can shield the acrylic from various acids.

- Polyurethane coatings are effective against caustic chemicals and solvents.

- Epoxy coatings protect against fatty acids and chemical cleaning detergents.

Potential for Yellowing

Another concern is the potential for acrylic to yellow over time. Standard pmma sheets can develop a yellowish tint after prolonged exposure to the sun’s ultraviolet (UV) rays. This color change is measured using a standard called the ASTM E313 Yellowness Index. For outdoor projects or items placed in direct sunlight, this yellowing can be a major drawback.

The lifespan of acrylic before it yellows depends on its type. A standard acrylic panel might show noticeable yellowing within 5 to 10 years of outdoor use. However, manufacturers offer UV-stabilized acrylic grades. These premium options are designed to resist UV degradation and can last 15 to 20 years or more before any significant color change occurs. Choosing the right type of acrylic is crucial for long-term clarity.

A disadvantage of acrylic becomes a dealbreaker only when it conflicts with your project’s core needs. The material’s disadvantages are not universal problems. Your budget, values, and project goals determine the right choice. This guide helps you decide if acrylic is suitable for you.

- Choose Acrylic if: You need superior optical clarity, a lightweight design, and good shatter resistance. You must be prepared for the required maintenance to keep the acrylic looking its best.

- Avoid Acrylic if: The item will face heavy physical wear or high impact. Avoid acrylic if sustainability is your top priority or you are on a strict budget.

You now have the knowledge to make a confident and informed choice about using acrylic.

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Can you fix scratches on acrylic?

Yes, you can fix minor scratches. Special acrylic polishes and a soft cloth can buff out light marks. Deeper scratches, however, are often permanent. This is a key disadvantage of the material’s soft surface.

Is acrylic plastic bad for the environment?

Acrylic’s environmental impact is a concern. Its production uses fossil fuels. The material is also not widely recycled and does not biodegrade in landfills. This makes disposal a significant environmental problem for pmma products.

What is a better alternative to acrylic?

The best alternative depends on your needs.

- Стекло is cheaper and more scratch-resistant but is heavy and can shatter.

- Polycarbonate is stronger and more impact-resistant but scratches more easily and costs more.

How do you clean acrylic safely?

You should clean acrylic surfaces carefully. Use mild soap and water with a soft microfiber cloth. Never use cleaners containing alcohol, ammonia, or other harsh solvents. These chemicals can cause permanent damage to the material.

See Also

Impact-Modified Acrylic: Understanding Its Properties, Uses, And Benefits

Acrylic Blocks: Exploring Their Design, Characteristics, And Versatile Uses

Acrylic Aquariums: Discovering Their Design, Advantages, And Practical Applications

Acrylic Risers: Unveiling Their Purpose, Key Attributes, And Diverse Uses

Acrylic Cosmetic Organizers: Essential Guide To Their Function And Utility