Acrylic trays offer a sleek, modern way to organize your home. The market for these stylish clear acrylic trays is projected to reach $326.97 million by 2024, driven by a love for minimalist design. However, not all acrylic trays are created equal. This guide helps you identify a quality clear acrylic tray from a flimsy one. You want trays that combine lasting durability with practical functionality, ensuring your clear acrylic trays are a smart investment.

Sign 1: Material Clarity and Thickness

The first sign of a quality clear acrylic tray is its material. You should inspect both its transparency and its thickness. These two factors directly impact the tray’s beauty and strength.

Look for Crystal-Clear Acrylic

High-grade acrylic should be exceptionally clear. It allows a light transmittance of 92%, which is comparable to glass. You should not see any yellow tint, cloudiness, or tiny bubbles within the material. Lower-quality acrylic trays often appear cloudy or have visible flaws. A premium material ensures your items are displayed perfectly. Many high-quality acrylic trays also meet food-grade standards. The FDA regulates materials for food contact under regulation 21 CFR 177.1010. This certification means the trays are safe for serving food, adding to their versatility. These clear acrylic trays offer a clean and safe option for any use.

Clarity for a Modern Presentation

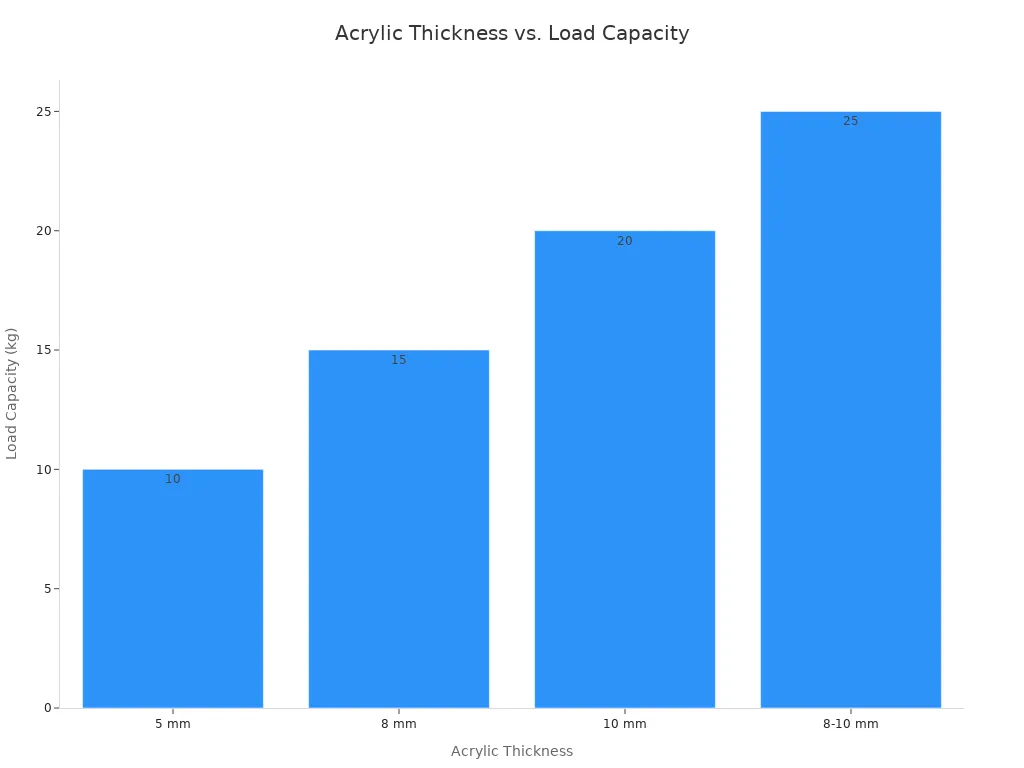

Thickness is a key indicator of durability. Good acrylic trays have a thickness of at least 4-5mm. This provides a solid feel suitable for home use. For heavier items or commercial settings, you should look for trays that are 8-10mm thick. These heavy-duty trays can handle more weight without bending. The right thickness improves the product presentation. It gives the trays a substantial, high-end feel. This enhanced visual appeal is crucial for retail displays or an elegant home presentation. Thicker clear acrylic trays create a better product presentation.

Pro Tip: The thickness of acrylic trays directly relates to their load capacity. A thicker tray is not just for looks; it is built for performance.

Choosing clear acrylic trays with proper clarity and thickness ensures you get a product that is both beautiful and built to last.

Sign 2: The Finish of Clear Acrylic Trays

An excellent finish is a hallmark of a quality clear acrylic tray. The edges tell you a lot about the manufacturing process and the overall care taken in its creation. You should pay close attention to how the sides and corners are finished.

Inspect for Polished Edges

A premium tray will have smooth, polished edges that feel like glass. Manufacturers use specific techniques to achieve this high-end look. The two most common methods are flame polishing and diamond polishing. Each method produces a different result on acrylic trays.

Polishing Techniques at a Glance 🔍

- Flame Polishing: This quick method uses a hot flame to melt the acrylic surface, creating a smooth finish. It works well for simple, straight edges on thinner clear acrylic trays.

- Diamond Polishing: This superior technique uses a diamond-tipped cutter to shave the acrylic, resulting in a perfectly flat, sharp, and optically clear edge. It is the preferred method for high-quality acrylic trays, especially thicker ones.

You can often tell the difference just by looking. Diamond-polished edges are exceptionally clear and precise, reflecting the higher craftsmanship of the trays.

Avoid Sharp, Unfinished Sides

You should always run your fingers along the edges of the trays. Low-quality clear acrylic trays often have sharp, unfinished, or roughly sawn edges. These are not just unappealing; they can be a safety hazard, capable of scratching you or your furniture. These rough edges indicate a rushed, low-cost manufacturing process.

A well-made product feels good to the touch. The corners should be smooth and slightly rounded for safety, even if the edges are diamond-polished for a crisp look. Poorly finished trays might also show signs of “crazing,” which are tiny stress cracks caused by improper flame polishing. These cracks compromise the strength and appearance of the clear acrylic trays. Choosing trays with a flawless, polished finish ensures you get a product that is safe, durable, and beautiful.

Sign 3: Joint and Seam Construction

The construction of the joints and seams tells you a lot about the craftsmanship of acrylic trays. How the individual pieces are put together is a major indicator of strength and quality. You should examine the corners and edges where the sides meet the base.

Check for Invisible Seams

High-quality clear acrylic trays have seams that are almost invisible. This is achieved through a process called chemical bonding, not simple gluing. This method creates a flawless and incredibly strong connection between the pieces.

How Chemical Bonding Works 🧪

- Manufacturers use a special solvent cement.

- The solvent melts the bonding surface of the acrylic.

- This process fuses the pieces into one unified piece.

- The result is a chemical bond that is as strong as the acrylic itself.

In contrast, poorly made clear acrylic trays often have messy seams. You should look for imperfections like a “cloudy look half way up” a seam or areas that look like “frost on a windshield.” The presence of many small bubbles or a “visible hazing” effect are clear signs of a low-quality manufacturing process. These flaws weaken the trays and ruin their clean look.

Strong Joints in Acrylic Trays

Strong joints are essential for the durability of your trays. The chemical bonding process ensures the corners can withstand daily use without cracking or separating. When you inspect acrylic trays, the joints should feel completely solid, as if the tray was made from a single piece of material.

Avoid clear acrylic trays with visible glue, messy residue, or separate corner pieces. These are shortcuts that point to poor craftsmanship. Trays constructed this way are likely to fail, especially if you use them to carry heavier items. A quality clear acrylic tray has clean, strong joints that guarantee both beauty and long-term function. Choosing trays with superior construction means you are investing in a product built to last.

Sign 4: The Weight and Solid Feel

The physical weight of acrylic trays offers important clues about their quality. When you pick up a tray, its heft can tell you a lot about the material and manufacturing process. You should always trust your sense of touch when evaluating these products.

Feel for Substantial Heft

A quality clear acrylic tray should feel solid and substantial in your hands. It should not feel light or flimsy. This satisfying weight comes from the density of the material used. High-grade acrylic has a density of 1.19 g/cm³, similar to high-quality plastics. When you hold two different clear acrylic trays, the heavier one often indicates a better product. This heft provides a sense of luxury and permanence. Lightweight trays, on the other hand, often suggest thinner, cheaper materials that may not last. You want trays that feel dependable.

How Weight Signals Durability

Weight is a direct signal of durability. Heavier acrylic trays are typically made from cast acrylic, which can be produced in much thicker sheets than its extruded counterpart. While both types share the same base density, the ability to create thicker cast acrylic results in stronger, more robust trays. This added thickness and weight contribute directly to the product’s overall durability. These sturdy trays are less likely to bow or crack under the weight of your items. When choosing clear acrylic trays, remember that a heavier feel often means you are getting a product built for longevity.

Quick Tip: When shopping online, check the product specifications for the item’s weight. A heavier weight for a given size usually points to thicker, higher-quality clear acrylic trays.

Sign 5: Choosing the Right Acrylic Trays for Durability

The final sign of quality involves understanding the material itself. Choosing the right acrylic trays means looking at the type of acrylic used and any protective features. These factors are crucial for long-term durability and appearance.

Understand Acrylic Types

You will find two main types of acrylic: cast and extruded. Manufacturers create cast acrylic by pouring liquid monomer into a mold, which results in a stronger material. Extruded acrylic is pushed through a machine, which is a less expensive process. For high-quality acrylic trays, you should look for cast acrylic. It offers superior durability and a better finish. Cast acrylic is more scratch-resistant, with a Rockwell hardness rating of 102 R.

Cast vs. Extruded: A Quick Comparison

Feature Cast Acrylic Extruded Acrylic Manufacturing Poured into a mold Pushed through a die Scratch Resistance More resistant Less resistant Chemical Resistance Better resistance Lower resistance Cost More expensive Less expensive

While more expensive, cast acrylic provides the strength and clarity you want in premium trays. These clear acrylic trays are a better long-term investment.

Check for Protective Features

You should also check for special coatings that enhance the trays. Many high-end acrylic trays include a UV-resistant coating. This feature is very important if the trays will be near a window.

A UV coating provides several key benefits:

- It blocks up to 99% of harmful UV rays.

- It prevents the clear acrylic trays from turning yellow over time.

- It protects any items you place on the trays from fading.

This protection keeps your clear acrylic trays looking crystal-clear for years. Some coatings also add an extra layer of scratch resistance. These protective features ensure your trays maintain their beauty and function, making them a reliable choice for any home.

You now know the five signs of a quality clear acrylic tray. Remember to check for clarity, smooth edges, seamless joints, a solid feel, and material durability. Acrylic trays are a smart investment. They weigh over 50% less than glass trays and offer 15-20 times more impact resistance. These clear acrylic trays provide excellent functionality and longevity.

Use this checklist to select trays that offer lasting beauty and functionality. You can find clear acrylic trays that enhance your presentation. With proper care, these trays provide years of reliable functionality and style.

FAQ

How do I clean my acrylic tray?

You should use a soft microfiber cloth with mild soap and water. Avoid harsh chemicals or abrasive cleaners like ammonia. These can scratch the surface and cause cloudiness. This simple care keeps your tray looking new.

Are acrylic trays good for bathroom organization?

Yes, they are excellent for bathroom organization. Their water-resistant nature makes them perfect for holding perfumes, cosmetics, and toiletries. You can keep your counters tidy and stylish.

What are the main benefits of acrylic trays over glass?

The main benefits of acrylic trays are their durability and light weight. Acrylic is much more shatter-resistant than glass. It is also lighter, making it easier and safer for you to handle daily.

Can I use these trays for commercial product displays?

Absolutely. High-quality trays create elegant product displays. Their crystal clarity showcases items beautifully without distraction. The benefits of acrylic trays include enhancing visual appeal for retail environments. They also work well for bathroom organization in hotels.

See Also

Choosing and Caring For Your White Acrylic Trays

Exploring Round Acrylic Trays: Designs and Everyday Applications

Styling Clear Acrylic Trays for Contemporary Home Decor