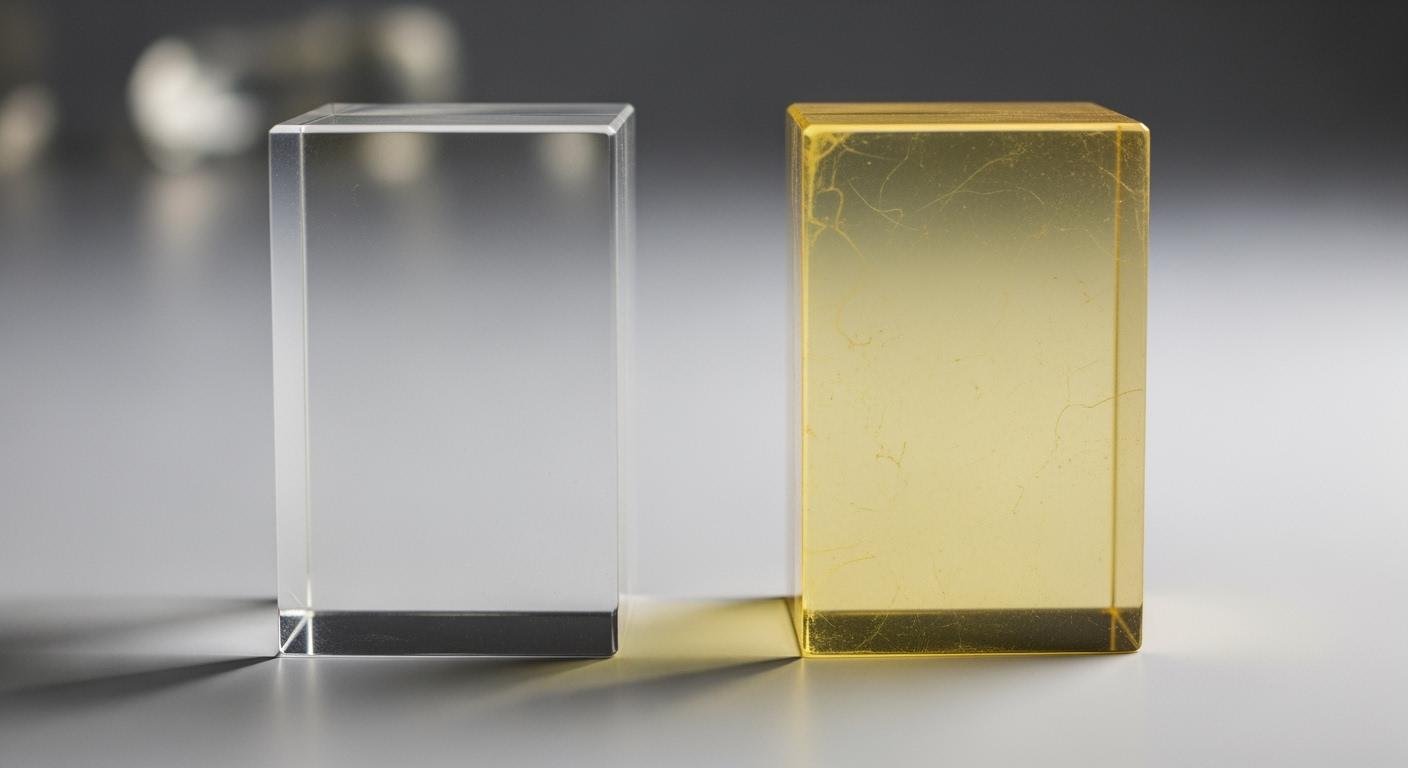

Do acrylic blocks yellow? The answer is yes, some acrylic can experience yellowing. High-quality, uv-stabilized acrylic, however, offers excellent resistance.

The surprising truth is that the material itself is not always the problem. The specific type of acrylic and its environmental exposure are the real culprits behind acrylic yellowing. This repeated exposure ultimately causes the unwanted discoloration. Understanding these factors is key to ensuring lasting clarity for any acrylic piece.

Why Do Acrylic Blocks Yellow?

The yellowing of acrylic is not a simple flaw. It is a chemical process driven by specific factors. Understanding these causes helps users choose the right material and protect it. The main culprits are light exposure, the manufacturing process, and environmental contaminants.

The Science of Yellowing: UV and Oxidation

Sunlight contains ultraviolet (UV) light, a powerful form of energy. Intense uv exposure is a primary cause of acrylic degradation. This process, known as photodegradation, involves two key reactions: chain scission and oxidation.

- UV radiation directly attacks the long polymer chains that give acrylic its strength. This exposure causes the chains to break apart, a process called chain scission.

- This breakage reduces the material’s molecular weight. It makes the acrylic weaker and more fragile over time.

Simultaneously, the energy from the light creates unstable free radicals within the material. These radicals react with oxygen in the air. This chemical reaction is called oxidation. The process of oxidation creates new molecular structures inside the acrylic. These new structures absorb visible light, which results in a yellow or brownish discoloration. High temperatures accelerate oxidation because they make the molecular chains more mobile and susceptible to damage. This combined attack from light and oxygen is what causes the unwanted yellowing.

Cast vs. Extruded: The Quality Difference

Not all acrylic is created equal. The manufacturing method significantly impacts its resistance to yellowing. The two main types are cast acrylic and extruded acrylic.

Note: Cast acrylic offers superior long-term clarity and is the recommended choice for applications requiring durability and resistance to discoloration.

Cast acrylic is made by pouring liquid monomer into a glass mold. The liquid then cures and hardens into a solid sheet. This process creates very long, strong polymer chains with a high molecular weight. These robust chains are inherently more resistant to photodegradation and oxidation.

Extruded acrylic is made by pushing heated acrylic polymer through a die to form a sheet. This continuous process is faster and cheaper. However, it results in a material with a lower molecular weight. The shorter polymer chains in extruded acrylic are more vulnerable to the effects of UV light and oxidation, making it prone to yellowing faster with prolonged exposure.

While both types have some natural UV resistance, their performance over time differs greatly. A case study of outdoor lightboxes showed cast acrylic maintained 98% clarity after 18 months, while extruded panels showed visible yellowing.

| Property | Cast Acrylic | Extruded Acrylic |

|---|---|---|

| UV Resistance | Excellent | Good |

| Weathering Stability | 10+ years | 3–5 years |

This data shows why choosing cast acrylic is a crucial step in preventing the issue of when acrylic blocks yellow.

Heat, Chemicals, and Environmental Pollutants

Beyond direct light exposure, other environmental factors can cause or speed up acrylic yellowing. Heat, harsh chemicals, and air pollution all contribute to the degradation of the material.

Harsh cleaning agents are a major threat. Cleaners containing strong acids, alkalis, or solvents can chemically attack the acrylic surface. This chemical exposure breaks down the polymer matrix, leading to immediate discoloration and brittleness. It is a direct cause of damage that weakens the entire structure.

Environmental pollutants also play a role, especially in urban areas.

- Smog contains nitrogen oxides and sulfur oxides.

- These pollutants react with moisture in the air to form weak acids.

- These acids settle on the acrylic surface, promoting oxidation and hydrolysis reactions that accelerate material degradation.

This constant exposure to a combination of light, heat, and pollutants creates a harsh environment. Lower-grade acrylic is particularly susceptible to these factors, which explains why some acrylic blocks yellow much faster than others.

How to Prevent Acrylic Yellowing

Preventing yellowing in acrylic is achievable with the right knowledge and practices. The process involves selecting the correct material from the start and following proper care guidelines. These prevention methods protect the acrylic from the environmental factors that cause discoloration. Individuals can maintain the clarity of their acrylic blocks for years by making informed choices.

Choose UV-Resistant Cast Acrylic

The most effective step in preventing yellowing is choosing the right type of acrylic. Cast acrylic is significantly more resistant to UV light and oxidation than its extruded counterpart. The manufacturing process for cast acrylic creates a material with a higher molecular weight. This robust structure better withstands the damaging effects of light exposure. While extruded acrylic is cheaper, it is more vulnerable to degradation.

Cast Acrylic costs 20% – 50% more. It’s a premium material best reserved for long-term or high-impact applications.

For projects requiring maximum longevity and clarity, selecting a uv-stabilized acrylic is essential. Many high-grade materials meet specific industry and military standards, which guarantee their performance against UV exposure and heat. These specifications are a reliable indicator of quality and resistance to yellowing.

| Product Name | Description | Governing Specification |

|---|---|---|

| Poly II | Heat-resistant, preshrunk acrylic | MIL-P-5425 |

| Poly 76 | Crosslinked, preshrunk acrylic sheet | MIL-P-8184 |

| Poly 84 | Superior craze and solvent resistance | MIL-P-8184 |

| Poly 2000 | Stretched Acrylic Sheet | MIL-P-25690 |

| Polycast UV-SC | UV Blocking & Solar Heat Control | Meets All Mil-Specs |

Choosing a product that meets these standards ensures the acrylic has been tested for durability and resistance to the factors that cause yellowing and long-term oxidation.

Proper Cleaning and Maintenance

Proper maintenance is one of the most critical prevention methods for acrylic. Dirt and grime can trap pollutants that accelerate oxidation. Harsh chemical cleaners cause direct damage, leading to immediate discoloration. Users should always use gentle, acrylic-safe products.

Recommended cleaning solutions include:

- Specialized Cleaners: Products like Novus 1 are formulated specifically for acrylic. They clean effectively without harming the material’s surface.

- Mild Soap and Water: A simple mixture of mild dish soap and warm water is a safe and effective alternative for cleaning acrylic.

The tools used for cleaning are just as important as the solution. Abrasive materials create micro-scratches that dull the surface and trap dirt, speeding up the oxidation process.

- Microfiber Cloths: These soft, non-abrasive cloths are the best choice. They clean without scratching and do not leave behind lint.

- Soft Sponges: A soft sponge designed for delicate surfaces can be used for tougher spots, but abrasive pads should always be avoided.

Regular cleaning prevents the buildup of harmful contaminants. The ideal frequency depends on the environment.

- Clean acrylic items approximately every 4 to 6 weeks in a typical indoor setting.

- Increase cleaning frequency for items in high-traffic areas or harsh environments.

- Weekly cleaning may be necessary to prevent significant dirt accumulation and limit the effects of oxidation.

Smart Placement and Use

Strategic placement can significantly reduce the risk of acrylic yellowing. Limiting direct exposure to intense sunlight is a simple yet effective way to prolong the life of any acrylic piece. Placing items away from south-facing windows or under awnings minimizes the daily dose of UV light. This simple step reduces the rate of oxidation.

For items that must endure constant light exposure, applying protective films offers an excellent solution. These transparent films act as a barrier, blocking harmful UV radiation before it reaches the acrylic surface.

- Products like 3M™ Industrial Protective Film 7070UV are designed to adhere to plastic surfaces and provide UV and weather resistance.

- Some manufacturers offer acrylic sheets with built-in protection. ACRYLITE® OP-3 AR1, for example, has a coating that resists abrasion and chemicals while filtering UV light.

- These protective films are one of the best prevention methods for both new and existing installations.

There are special considerations for outdoor applications. Items placed outdoors face constant, intense exposure to light and pollutants. For these uses, selecting a high-grade, UV-blocking cast acrylic is non-negotiable. Combining this superior material with additional protective films provides the ultimate defense against yellowing and ensures the acrylic remains clear and stable for over a decade.

Dealing With Discolored Acrylic

When an acrylic block shows signs of yellowing, it may not be a lost cause. The solution depends on the severity of the damage. Understanding the depth of the discoloration is the first step toward restoration. Some issues are only surface-deep, while others indicate a more serious problem.

How to Identify Yellowing Depth

Figuring out the extent of the damage is crucial. The process of how to identify yellowing involves a simple visual inspection. Users can examine the acrylic block from the side. If the yellow tint appears concentrated on the surface with a clearer interior, the degradation is likely superficial. However, a uniform yellow color throughout the entire thickness of the acrylic suggests deep chemical degradation. Measuring yellowing this way helps determine if a repair is possible.

Can Surface Yellowing Be Polished Away?

Yes, surface-level yellowing and minor discoloration can often be polished away. Polishing removes a very thin top layer of the material, revealing the clear acrylic underneath. This process can restore the original clarity.

Caution: Improper polishing can cause more harm than good. High speeds can burn the acrylic, creating cloudy spots. Polishing only one small area can also create a distorted “wave” effect on the surface.

For a successful restoration, follow these steps:

- Clean the Surface: Gently wash the acrylic with mild soap and water, then dry it with a soft microfiber cloth.

- Apply Polish: Use a polishing compound made for acrylic on a clean buffing pad.

- Buff the Area: Move the polisher in controlled circular motions at a low speed. Apply steady, even pressure.

- Final Polish: Use a finer polish with a clean cloth to achieve a smooth, glossy finish.

- Inspect: Check the acrylic under a bright light for any remaining imperfections.

When Replacement Is the Only Option

Sometimes, the damage is too extensive for a simple fix. If the yellowing has penetrated the entire material, it signals that widespread chemical degradation has occurred. This type of deep discoloration means the polymer structure itself has broken down. In these situations, polishing will not remove the yellow hue. The only effective solution is to replace the acrylic piece. This is especially true for lower-quality materials that have suffered from long-term UV exposure.

The issue of when acrylic blocks yellow is largely preventable. The yellowing of acrylic is not an inevitable fate. The solution rests on two key actions: choosing the right material and practicing proper care. High-quality cast acrylic offers remarkable durability and can remain clear for over 10 years outdoors. This makes it the superior choice for preventing discoloration. By selecting this material and following simple maintenance, users can confidently enjoy their acrylic pieces without fear of acrylic yellowing. The problem of why acrylic blocks yellow has a clear solution.

FAQ

Is yellowed acrylic weaker?

Yes, it is. The chemical process of oxidation that causes yellowing also breaks down the material’s internal structure. This degradation makes the acrylic more brittle and prone to cracking over time. The piece loses its original strength and durability.

Does all clear plastic yellow like acrylic?

Different plastics have varying resistance. Polycarbonate, for example, often yellows faster than high-quality acrylic. Cast acrylic with UV protection offers superior defense against yellowing and oxidation, making it a more durable choice for long-term clarity.

Can heat alone cause yellowing?

High heat speeds up the chemical reaction of oxidation. It makes the material more vulnerable to damage from light exposure. This accelerated oxidation process is a direct cause of discoloration, especially in lower-grade materials.

Tip: Always keep acrylic items away from direct heat sources like radiators or intense spotlights to prevent premature aging and damage from oxidation.

How long does cast acrylic stay clear?

High-quality cast acrylic can remain clear for over a decade, even with outdoor use. Its dense molecular structure provides excellent resistance to the chemical process of oxidation. This strong defense against oxidation ensures lasting transparency. The process of oxidation is the primary cause of yellowing.

See Also

Acrylic Blocks: Understanding Their Nature, Characteristics, and Uses

Unveiling Acrylic Tray Truths Through Simple and Creative DIY Projects

Choosing and Maintaining White Acrylic Trays: A Comprehensive Guide

Acrylic Aquariums: Exploring Their Design, Benefits, and Practical Uses

Anti-static Acrylic: Defining Its Science, Mechanics, and Diverse Uses