Many people ask why acrylic expensive is a common perception, and the answer lies in its inherent value, not just its production cost. The high price of high-quality acrylic is justified by a combination of premium raw materials and a complex manufacturing process. This material offers superior strength, clarity, and longevity compared to glass or other plastics, making the initial investment worthwhile. The growing demand for acrylic sheets further demonstrates its recognized worth.

| Metric | Value |

|---|---|

| 2023 Market Size | $4.0 Billion |

| 2031 Projected Market Size | $6.2 Billion |

| CAGR (2024 – 2031) | 5.9% |

This strong market demand confirms that while the notion that acrylic expensive is true, its performance makes the cost and price a sound investment for many applications.

Core Cost Drivers: Why Is Acrylic So Expensive?

To understand the answer to why is acrylic so expensive, we must look at the journey from raw material to finished product. The final price reflects a complex process involving specialized materials, energy-intensive manufacturing, and detailed craftsmanship. These core factors directly influence the overall acrylic pricing structure.

Premium Raw Materials and Production

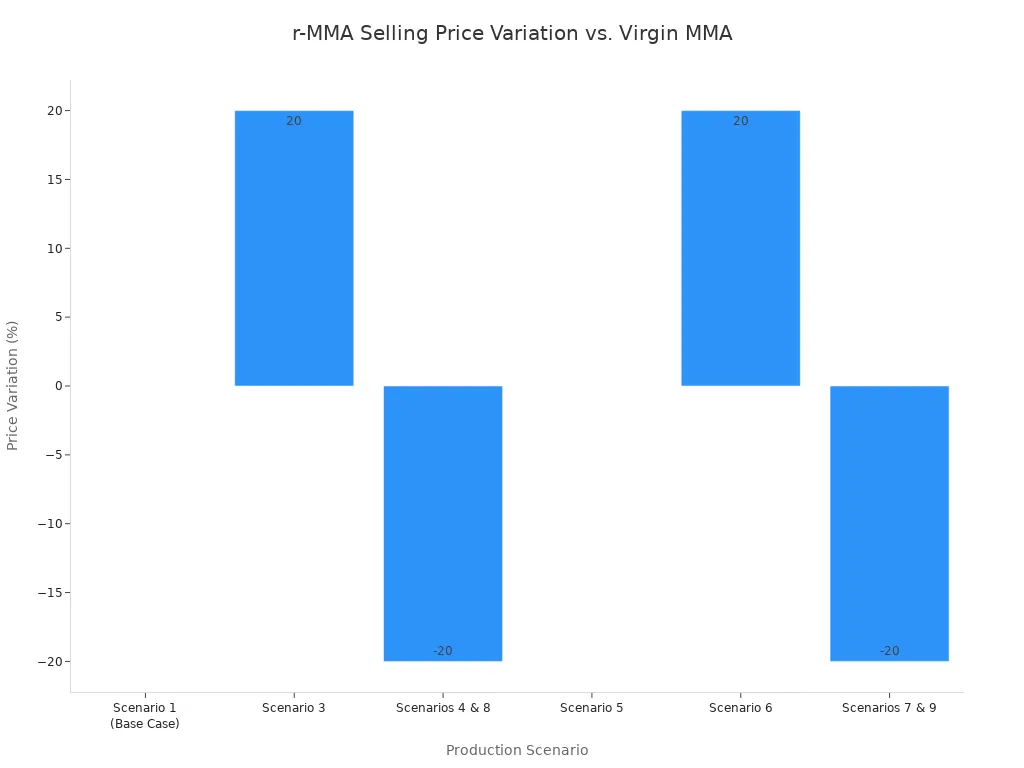

The creation of high-quality acrylic begins with premium raw materials. The primary component is a high-purity, petroleum-based polymer called methyl methacrylate (MMA). While recycled MMA (r-MMA) is an option, its price and quality can vary dramatically. This makes virgin MMA the standard for producing clear, durable acrylic sheets.

Note: The assumption that recycled materials are always cheaper is a common misconception. The demand for sustainable products can sometimes drive the price of high-purity recycled MMA to be equal to or even higher than virgin material.

The price of r-MMA depends on factors like the purity needed and the initial investment in recycling technology. As the table shows, achieving a quality acceptable for the market often means the cost is similar to virgin MMA.

| Scenario | Feedstock | CAPEX (M USD) | r-MMA Selling Price | Purity/Quality |

|---|---|---|---|---|

| 1 (Base Case) | Mixed Scraps | 10 | Virgin Price | Acceptable for EU market |

| 3 | Mixed Scraps | 10 | 20% Premium | Higher purity requested |

| 4 & 8 | Mixed Scraps | Low (second-hand/cheap tech) | 20% Discount | Lower quality |

| 7 & 9 | Very Low Quality PMMA Scraps (free) | 10 | 20% Discount | Pure enough to enter market |

Manufacturing, especially for cast acrylic sheets, is also an energy-intensive process. It requires heating the liquid MMA in large ovens for many hours to ensure it cures perfectly. This high energy consumption adds significantly to the production cost.

The High Cost of Thicker Acrylic Sheets

The price of acrylic sheets increases dramatically with thickness. Producing thick, high-quality acrylic sheets (over one inch) is a specialized and expensive process. It requires the cast manufacturing method, which is more time-consuming and requires greater precision than other methods.

The process for making thick acrylic sheets involves several careful steps:

- Preparing Raw Materials: Technicians mix liquid MMA with catalysts and other additives to enhance strength and clarity.

- Pouring into Molds: The mixture is poured between two large, polished glass plates that serve as a mold.

- Polymerization in Ovens: The molds are placed in large, temperature-controlled ovens. The liquid slowly polymerizes, or turns into a solid. This step can take many hours or even days for very thick acrylic sheets.

- Cooling and Mold Removal: The sheets are cooled gradually to prevent stress and cracking. Workers then carefully separate the solid acrylic sheets from the glass molds.

- Cutting and Finishing: Finally, the large sheets are inspected, cut to size, and polished.

This meticulous, multi-day process explains why thicker acrylic sheets are so much more expensive. The high demand for these durable sheets in applications like furniture and aquariums keeps their pricing firm.

Labor, Craftsmanship, and Finishing

The final factor making acrylic expensive is the manual labor involved in creating finished goods. Many popular items, like clear acrylic boxes, are not mass-produced by machines. They require skilled artisans to cut, assemble, and polish each piece by hand.

Consider the journey of imported acrylic products. Items like acrylic boxes cannot be stacked flatly for shipping. This limitation drastically increases freight costs. For example, a shipping container can hold four times as many stackable items as non-stackable ones of a similar size. This means the shipping cost per item for bulky products like acrylic boxes is much higher.

This combination of factors—skilled labor for assembly, meticulous polishing for a flawless finish, and high shipping costs for imported acrylic goods—all contribute to the final price tag. The high demand for beautifully crafted items like acrylic boxes justifies this intensive process. The result is a premium product where the cost reflects true craftsmanship.

The Value Behind the Price: Performance and Design

The high price of acrylic is not just about production cost. It reflects superior performance and design capabilities that other materials cannot match. Understanding these benefits helps explain why the material is a valuable investment.

Superior Strength and Durability

Acrylic is significantly stronger and more durable than glass. It has a much higher impact strength, meaning it can absorb energy without shattering. This makes acrylic sheets a safer choice for displays, barriers, and signs. While standard acrylic is softer than glass, many products use a special coating to improve scratch resistance.

Did You Know? Coated acrylic sheets are much more resistant to abrasion than uncoated ones. Minor scratches on standard acrylic can often be buffed out, a repair that is impossible with glass. This durability reduces the need for frequent replacements in busy retail spaces, justifying the initial pricing.

Unmatched Optical Clarity and UV Resistance

High-quality acrylic sheets offer exceptional visual performance. They can transmit up to 92% of visible light, which is more than most types of glass. This provides crystal-clear views without the slight green tint found in thick glass panels.

Additionally, acrylic provides excellent protection from the sun.

- It naturally blocks over 98% of harmful UV rays.

- This UV resistance prevents the material from turning yellow over time.

- It maintains its clarity for 10 years or more, unlike other plastics that degrade quickly.

This long-lasting clarity makes acrylic sheets perfect for protective frames and outdoor applications.

Versatility in Modern Design

A key reason why is acrylic so expensive is its incredible design flexibility. As a thermoplastic, acrylic can be heated and molded into complex curves and shapes. This process, called thermoforming, is not possible with glass. This versatility allows designers to create everything from the iconic “Ghost Chair” to the sleek, curved fixtures seen in Apple Stores. The ability to create unique, modern designs makes the expensive material a favorite for architects and brands. The perception that acrylic expensive is often tied to these custom, high-end applications.

Why Is Acrylic Expensive Compared to Alternatives?

Understanding why is acrylic so expensive involves comparing it to other common materials. The choice between acrylic, glass, and other plastics often comes down to a balance of cost, safety, and performance for a specific project.

Acrylic vs. Glass: A Cost and Safety Trade-Off

Acrylic often presents a better value proposition than glass. While the initial price can be similar, acrylic is much lighter and stronger. Acrylic sheets weigh about 50% less than glass sheets of the same size. This makes installation easier and safer.

| Material | Weight (4′ x 8′ sheet, 1/4″ thickness) |

|---|---|

| Acrylic | Approximately 46 pounds |

| Glass | Approximately 96 pounds |

This weight difference reduces shipping and labor costs. For projects like deck railings, acrylic can be a budget-friendly choice compared to tempered glass, which has a higher cost. For example, tempered glass for a railing can cost between $15 and $20 per square foot. Acrylic’s impact resistance also makes it a safer option, as it is less likely to shatter.

Acrylic vs. Polycarbonate and Other Plastics

When compared to other plastics, acrylic sheets offer a unique blend of features. Polycarbonate is another popular clear plastic, but it is generally more expensive. The price for polycarbonate can be up to 35% higher than for acrylic.

Pro Tip: Acrylic has much better scratch resistance than polycarbonate or PETG. This makes it a better choice for high-touch surfaces where clarity needs to last.

While some plastics like PVC have high chemical resistance, others like polystyrene dissolve easily when exposed to common chemicals. Acrylic provides good resistance for most applications. The difference between cheap vs. premium acrylic often lies in its purity and manufacturing quality, which affects its durability and clarity.

Justifying the Investment for Your Project

Ultimately, the higher pricing of acrylic is an investment in quality. For applications needing a lightweight, durable, and crystal-clear material, acrylic sheets are often the best choice. The perception that acrylic expensive is true, but its long-term performance provides excellent value. Whether you need a safe barrier, a beautiful display, or a unique design element, the benefits of acrylic justify its cost.

The label acrylic expensive is ultimately justified. The material’s high price is a direct result of its complex production, superior qualities, and unique design capabilities. This cost reflects its growing role in major sectors like construction, where it is valued for being lightweight and shatter-resistant.

For applications demanding a premium blend of durability, clarity, and sophisticated aesthetics, acrylic provides long-term value. This makes the expensive material a worthwhile investment for the future. 💡

FAQ

Why is acrylic more expensive than glass?

Acrylic’s higher price comes from its complex manufacturing process and superior qualities. It is much stronger and lighter than glass. This makes it safer and easier to install, adding to its overall value for many projects.

Does acrylic turn yellow over time?

High-quality acrylic does not turn yellow. It contains special UV-resistant properties that protect it from sunlight. This allows the material to maintain its crystal-clear appearance for over 10 years, unlike many cheaper plastics that degrade and discolor.

Can you repair scratched acrylic?

Yes, you can often repair minor scratches on acrylic.

You can use a special polishing compound to buff out light surface scratches. This is a major advantage over glass, which cannot be easily repaired once it is scratched or chipped.

Is thicker acrylic always better?

Thicker acrylic is stronger and more rigid, making it ideal for structural uses like furniture or large aquariums. However, thinner sheets are lighter and more affordable for projects like picture frames or small signs. The best thickness depends on your specific needs. 💡

See Also

Acrylic (PMMA): Understanding Its Properties and Diverse Applications

Impact-Modified Acrylic: Exploring Its Features and Practical Uses

Acrylic Risers: Unveiling Their Features and Versatile Applications

Acrylic Aquariums: Discovering Their Unique Features and Benefits

Cast Acrylic Sheet: Key Properties and Widespread Industrial Applications